Method and system for observing a cement kiln process

(22) 21.10.2022

(43) 27.04.2023

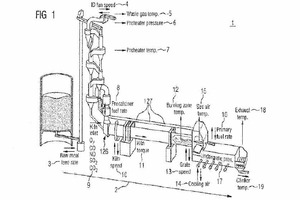

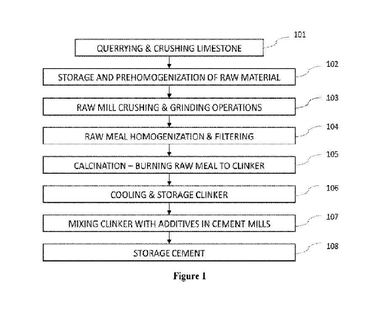

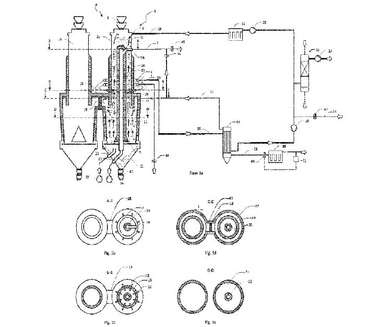

(57) The current disclosure describes a method of observing a behaviour of a cement kiln process, the method comprising using an artificial intelligence model and forcasting at least one variable based on an artificial intelligence model, wherein the variable depends on the kiln process. Also described is a system for observing a behaviour of a cement kiln process, the system comprising a recording device for data of sensor signals, a model to calculate a forecast of a variable, wherein the variable depends on the kiln process, and in particular a user interface for displaying a forecast of a variable, wherein the variable depends on the kiln process.

(71) Siemens Aktiengesellschaft, Werner-von-Siemens-Straße 1, 80333 München (DE)