State-of-the-art explosion protection for dedusting of coal grinding plants

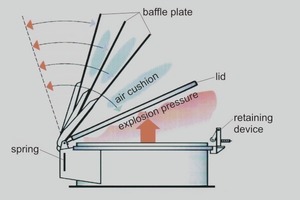

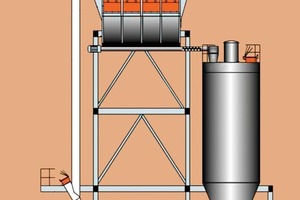

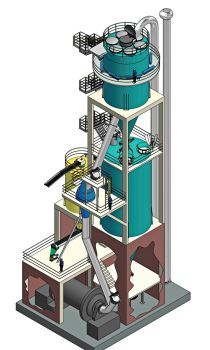

Summary: With dedusting of coal grinding plants, the state of the technology is determined by the explosion protection measures, the filtration performance and the design of the plant. To ensure safe operation of a plant, only certified and tested concepts and components should be used for its design and manufacture. With plants protected against explosion, such issues will always affect the plant’s resistance, its explosion relief venting and its explosion decoupling systems. Economic factors, where the aim is minimising the filter level and lean design, should not be forgotten with dedusting and it is important that plants are aligned to the latest state of technological development. With their years of experience and continuing development in the area of dedusting for coal grinding plants, Intensiv-Filter and Thorwesten Vent have succeeded in implementing the state of the art.

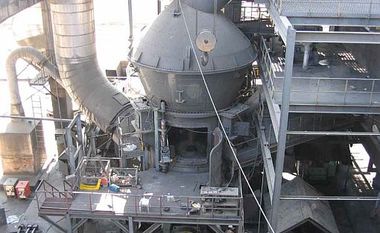

Coal is still considered the most important fuel for the manufacture of cement, lime and gypsum. In the German cement industry, despite the increasing use of secondary fuels, the proportion of the total thermal energy requirement is still around 40 % (36.6 million GJ/a) [1]. This value has stabilised over the past few years and the trend is anticipated to be rising rather than falling. Worldwide, coal as a fuel for the cement industry is even more important since secondary fuels are used less and coal is often available locally, making it a low-cost energy source. Particularly...