Turning waste heat into clean energy

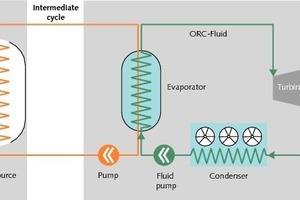

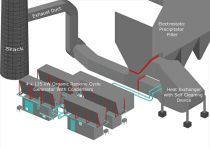

ABB and Holcim Switzerland have agreed to install ABB’s newly developed heat recovery and electrical power production system at their cement plant in Untervaz/Switzerland (Fig. 1). ABB’s state-of-the-art solution is based on the ORC (Organic Rankine Cycle) technology that makes it possible to turn waste heat into clean electricity (Fig. 2). Thanks to the use of waste heat as operating power, no fossil energy is required to run the power plant. Consequently, Holcim’s Untervaz operation will be able to considerably reduce its energy costs and operate the plant more efficiently. The contract comprises engineering, project planning, delivery, installation and commissioning of the complete turnkey package consisting of all power plant components such as turbine, generator and heat exchangers. ABB has the know-how to fully integrate the power plant into the entire cement production process, including electricity supply and the complete control system. The system is expected to be in operation by the end of 2011.

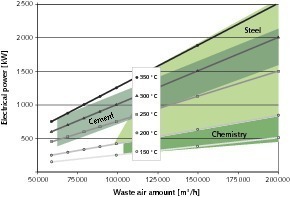

Markus Hepberger, plant manager at Holcim’s Untervaz operation, states: “ABB’s heat recovery system will allow us to produce 10.5 GWh of electrical energy per year (Fig. 3). This corresponds to a demand for energy of approximately 2000 households in Switzerland.” A future replacement of the existing planetary cooler will increase the power production up to 50 %. Then the cement plant will need 20 % less electricity to operate and will boost its productivity even further. Cement production typically has an enormous demand for energy. The clinker burning kiln requires temperatures of up to 1500 °C. Despite the fact that the modern plant re-uses most of the process exhaust heat for material pre-heating and drying a significant amount of medium temperature gas is vented through the stack. ABB’s heat recovery solution is a new integrated system for the efficient utilization of low and medium temperature waste heat in industrial plants. Waste heat with temperatures starting from only 150 °C can be economically used to generate electric power from 500 kW up to double-digit megawatts. Plant owners using ABB’s heat recovery system will benefit from lower operating costs thanks to an on-site, CO2-free power generation source, making them less dependent on rising electricity prices. End users benefit from lower capital expenditure by using standard components that are installed quickly and effectively by ABB’s professional planning and project execution teams.