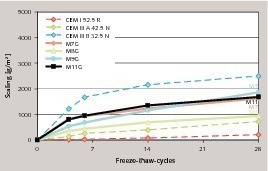

Evaluation of the performance of multi‑component cements

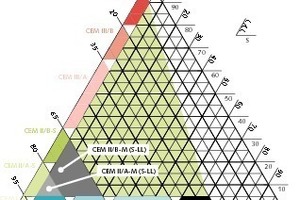

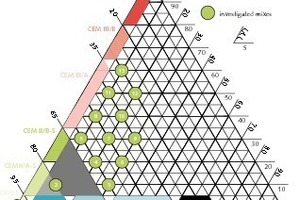

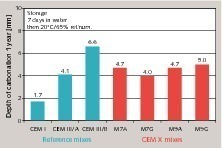

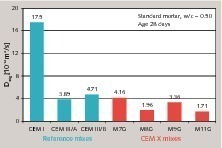

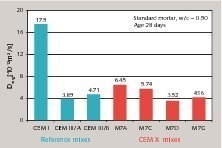

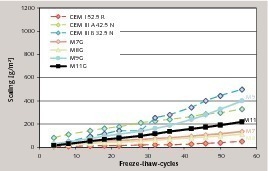

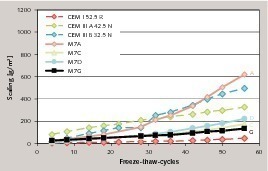

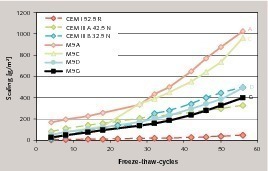

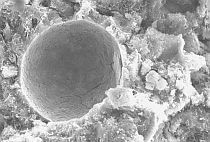

Multi-component cements (“CEM X”) do not differ in their behaviour and performance in concrete from those cements already defined in the cement standards. Their constituents are well known and have been used successfully for a long time. Only the composition has not yet been covered by the cement standards.