Optimization of the

thermal substitution rate – Part 1

By means of MI-CFD modeling, improvements to AFR thermal substitution rates (TSR) can be easily validated. Two case studies are presented where coal and natural gas were replaced with petcoke and AFR (SRF and BS).

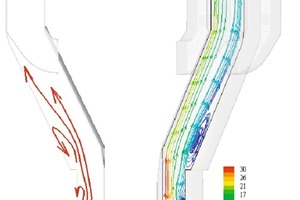

![3 Illustration of air-through precalciner riser duct [dimensions in mm]](https://www.zkg.de/imgs/tok_1c827357a58fbe3cd3613367df03e480/w300_h200_x400_y457_101531654_9d4837b4a2.jpg)

![10 Oxygen concentration [kg/kg] (cut off at 6 % O2)](https://www.zkg.de/imgs/tok_232b04f0c8f75d7eb4f7d2754d2c566d/w300_h200_x400_y400_101531553_75144a2a0b.jpg)

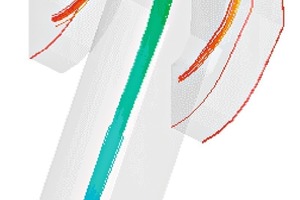

![11 Temperature distribution inside the precalciner riser duct chamber [in C°]](https://www.zkg.de/imgs/tok_7acc0b268eaab94e332766676bbb1c5e/w300_h200_x400_y400_101531533_9598fd44d2.jpg)

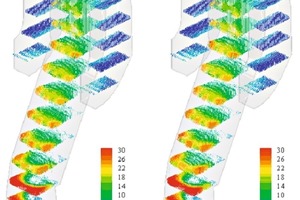

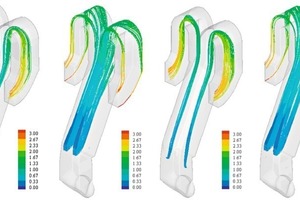

![13 Petcoke particles’ residence time in the riser duct (a = Base case, b = extended riser duct with lower burner location) [in sec.]](https://www.zkg.de/imgs/tok_b0265d19aab7d676b5bd058dd0a1dde4/w300_h200_x400_y375_101531570_1c5be104db.jpg)

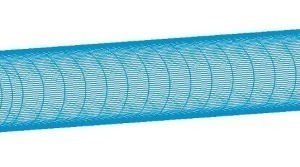

![15 Kiln hood, kiln burner and kiln layout [dimensions in mm]](https://www.zkg.de/imgs/tok_e71964fc1b13ec85d54a9a6c8d0cb140/w300_h197_x400_y98_101531544_9d400b1b3f.jpg)

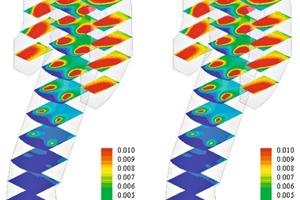

![18 Temperature profile [in °C] (Temperature at oven exit = 1077°C)](https://www.zkg.de/imgs/tok_4a00b8ac178a52c2b2fbf486018fe63a/w300_h200_x400_y195_101531597_45ea4bc28f.jpg)

![19 Oxygen concentrations [in mass %] (O2 concentration at oven exit = 5,75%)](https://www.zkg.de/imgs/tok_50b26d6e7c20e12549381d526198da42/w300_h200_x400_y148_101531658_a2c0531c5f.jpg)

![20 Velocity vector field with magnitude [in m/s]](https://www.zkg.de/imgs/tok_541d3a378bb035b3c78c9c73e90973c8/w300_h200_x400_y204_101531520_03e0950863.jpg)

![21 Kiln bed temperature along the kiln length [in °C/m]](https://www.zkg.de/imgs/tok_7f16118cc24aaa1daa7188bcba61f70e/w268_h154_x134_y77_101531617_ff1b7b1980.jpg)