Low-cost monitoring of filters

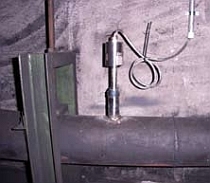

The requirement to detect reliably and quickly increased amounts of dust on the clean gas end is a permanent topic in all processes, in which dust is generated. The filter plants available on the market today undoubtedly have an excellent efficiency but there is no guarantee that filter breakdowns, cracks or minor leakages will not occur from time to time. The residual risk of a filter breakdown cannot be eliminated completely. However, it can be ensured by an appropriate technology that the failure will be detected immediately. The “Dusty” (Fig.) operates according to the triboelectrical...