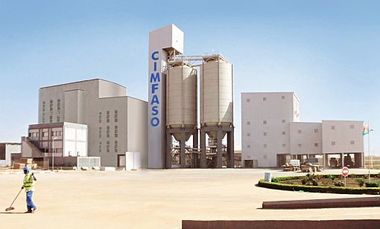

Electrical engineering and automation for a cement terminal at the port of Malmö/Sweden

Haver & Boecker supplied the complete electrical system and automation for this cement plant. The systems include the following components:

PCS7 process control system with CEMAT, according to HeidelbergCement standard

Gas-insulated medium voltage switchgear, 11 kV

Dry-type transformer 1600 kVA

Low voltage main distributor with compensation

Switching and control cabinet with S7-400/ET 200M, according to HeidelbergCement standard

Electrical grounding and lightning protection

Cable and installation material

IT network and infrastructure

Video monitoring of the loading stations as well as the entrances and exits

Interior and exterior lighting

Engineering and complete electrical installation and start-up

One challenge for the automation systems supplied by Haver & Boecker was adapting the PCS7 process control system to the silo processes so that clear and well-arranged process groups resulted, thus allowing easy operation and rapid fault detection (Fig. 4) The tanker trucks and wagons are automatically loaded according to the shipping orders thanks to the data exchange between the process control unit and the shipping system provided by Cementa AB. By cooperating closely with the HeidelbergCement Technology Center Brussels, the processes were optimised so that the terminal could be operated without operating personnel. After the start-up of the facility, the terminal was successfully handed over to Cementa AB in March, 2012, after almost 2 years of planning and construction work.

Haver & Boecker extends its thanks to the HeidelbergCement Technology Center Brussels, Cementa AB, the terminal operator, Ibau and all subcontractors for the excellent cooperation, without which this successful result in such a short time would not have been possible.