A framework and taxonomy for the classification of bulk material metering and dosing equipment within the cement industry

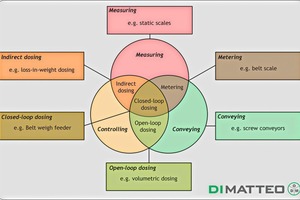

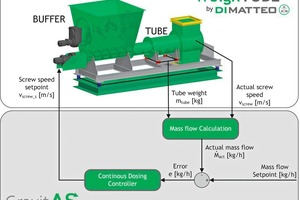

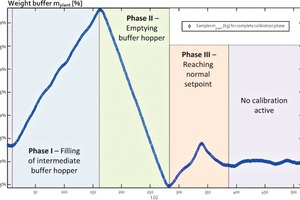

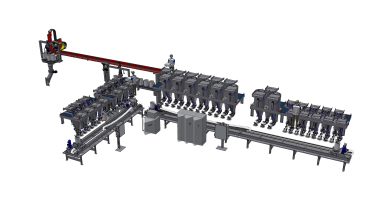

The proportioning of bulk materials is a key functional task within the overall process of cement manufacturing and all related transport and logistic systems. Even if many different system architectures have been proposed throughout the last decades, there is no systematic classification available, which allows a strategic decision for a specific methodology. This article proposes a general taxonomy for the classification of metering and dosing devices for bulk material. Based on the developed framework, an analysis of the typical range of products is carried out. Furthermore the novel ODM-WeighTube, a tubular gravimetric high-precision dosing system, is introduced as an example of the latest developments within the field of bulk material proportioning.

1 Introduction

The cement manufacturing process and all related transport and logistic systems are driven by strict requirements regarding the accurate proportioning of bulk materials from various sources. The corresponding integration of adequate parts of equipment requires the systematic selection of dosing and/or metering devices or scales and the subsequent consideration of the necessary weighing technologies. If the complete chain from the quarry and subsequent handling of raw materials to the dispatch of the final product in bags or as bulk cement is analysed, it is obvious that the...