Co-processing – resource preservation in a resource intensive industry

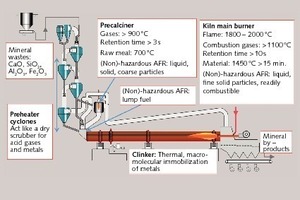

An increasing demand in emerging economies, combined with resource scarcity, pressure to reduce greenhouse gas emissions, increasing consumption and subsequent waste generation, makes low grade resources and waste treatment in resource intensive industries (RII’s) an interesting opportunity. The overall objective of this paper is to present best practices that constitute a benchmark for cement plants co-processing alternative fuels and treating hazardous waste.

1 Introduction

The development of a proper waste management infrastructure is not only required to protect human health and the environment, but it is necessary to sustain further development of their economies (Council Directive, 2000; IPPC, 2007). Many countries do not have a proper waste management infrastructure in place (Karstensen, 1998 and 2001b).

Often, the industry and/or the public society have limited options available to treat their waste in a cost-effective and an environmentally sound manner. For example, liquid organic hazardous waste, including oily waste, are frequently used in...