Combustor

(22) 30.07.2015

(43) 25.01.2018

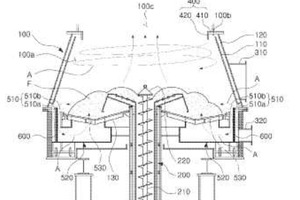

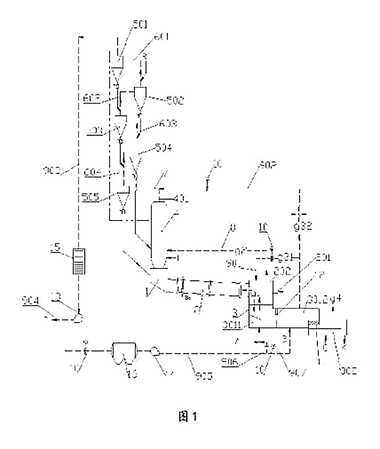

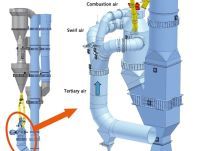

(57) A combustor according to the present invention comprises: a combustion chamber having a grate embedded therein and a combustion space formed above the grate; a fuel supply part downwardly connected to the center part of the grate so as to supply fuel to the upper part of the grate; an air supply part connected to the side part of the combustion chamber to be inclined on a horizontal plane, so as to supply combustion air such that the combustion air swirls in the combustion space; a clinker collection part downwardly communicating with the gap, which is formed between the inner wall of the combustion chamber and the grate, so as to collect, through the gap, the clinker generated by the combustion of the fuel in the combustion space; and a re-inflow channel passing through the grate from the clinker collection part to the combustion space such that the combustion air, having flowed out from the combustion space to the clinker collection part through the gap, re-inflows into the combustion space.

(71) Posco