Cutting mill combination for the comminution of heterogeneous materials in the cement industry

In the future, Schwenk Zementwerke KG, one of the largest cement and construction material manufacturers in Germany, is planning to even utilize other materials for the production of cement. Schwenk is especially considering using industrial waste which is a very heterogeneous material mix made up of foils, plastics, paper and wood.

Analysis determined by legislation

Legislation mandates in the Technical Instruction for Communitiy Refuse, an encompassing analysis of such materials, prior to thermal utilisation. So for example, is an analysis of the chlorine content important. In addition, the manufacturer is interested in the determination of the calorific value. In order to conduct the necessary tests, as a first step, the material has to be comminuted down to approximately 30-40 mm analytical fineness (< 500 μ).

Difficult comminution

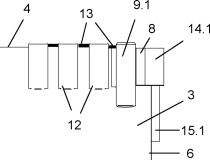

Since the material is very homogenous, the comminution of these materials was very problematic in the past. After extensive tests and studies the Schwenk KG decided to utilize the cutting mill combination Pulverisette 25/19 with integrated dust exhaust.

Simple quick cleaning and feeding

During the construction of this cutting mill combination great care was taken to avoid the disadvantages of prior generation cutting mills. By minimizing the dead spaces in the grinding chamber and by substantially simplifying the process of removing all grinding chamber parts, the cleaning effort is drastically reduced.

Beyond this, the connected sample exhaust ensures that the material can be fed relatively easily into the mill. An elaborate manual feeding with a pestle system is not necessary, such as in cases where the sample is granular. The Schwenk KG therefore plans to directly link the mill into the production process. An additional effect of the sample exhaust is that the utilized sieves do not clog the grinding chamber. They will be literally “vacuumed clean”. Tests in the Schwenk laboratory showed that the residual moisture of the material has to be below 20 %.

Cutting mill combinations in use

At the moment Schwenk Zementwerke KG is using two Fritsch cutting mill combinations, at their location in Allmendingen und Mergelstetten. The equipping of additional sites with these instruments is being considered.

In summary it can be asserted, that the Schwenk KG was able to substantially reduce the amount of time needed for the comminution of their laboratory samples. The comminution of some samples (for example tires) only became possible with the utilization of the Fritsch cutting mill combination. This instrument combination is therefore the first choice regarding to the comminution of heterogeneous materials.

//www.fritsch.de" target="_blank" >www.fritsch.de:www.fritsch.de