Drive train condition monitoring

Condition Monitoring has become an essential element for the digitalization of industry. The reasons are obvious: the smooth and uninterrupted availability of production facilities is top priority for companies operating plants, as this is the only way to guarantee maximum productivity from production systems. In an ideal situation, a condition monitoring solution should be a package from a single source, comprising an integrated system and services.

1 Introduction

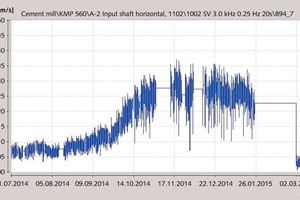

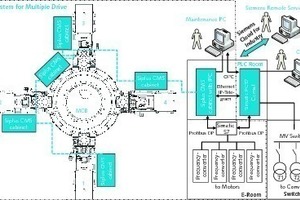

An efficient condition monitoring solution such as Siemens’ Drive Train Condition Monitoring (DTCM) is integrated into the automation system and monitors the entire drive train. The main focus is on motors and mechanical transmission systems, to ensure that potential damage is identified and rectified – or averted – at an early stage. This monitoring system also carefully analyzes how individual components operate together. The monitoring data is combined within a single system and is evaluated in detail by experts in the form of condition reports. This means that plant...