Effect of pre-crushing with a vertical shaft impactor (VSI) crusher on the performance of an industrial cement ball mill classification circuit

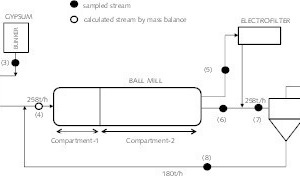

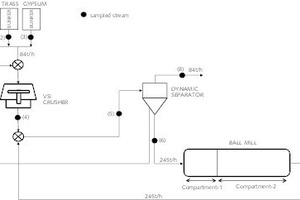

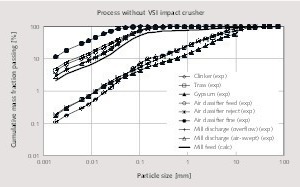

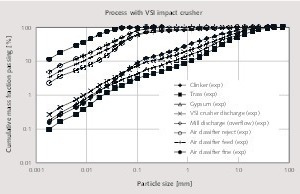

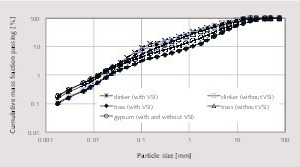

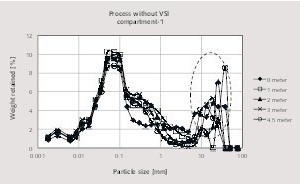

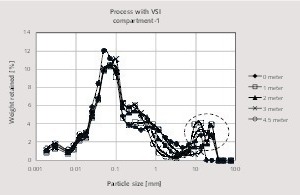

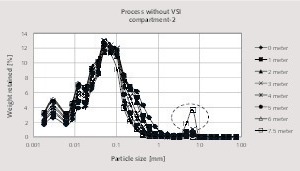

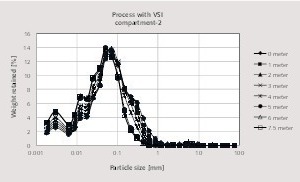

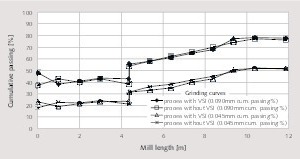

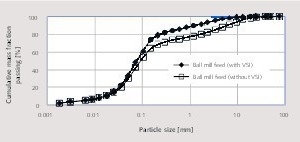

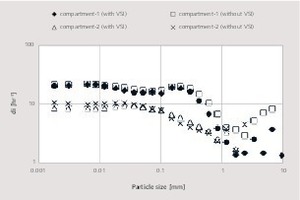

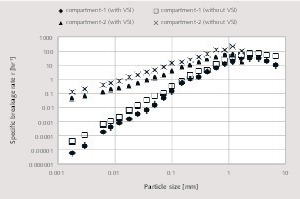

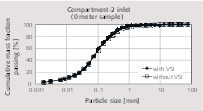

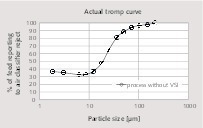

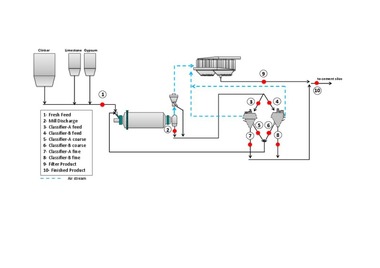

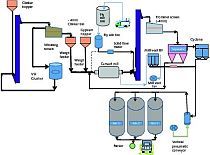

Grinding performance and circuit capacity change were investigated when an industrial scale VSI crusher was integrated into the two-compartment ball mill closed circuit. Semi-finish grinding application of a VSI crusher could result in 8 % capacity increase in cement throughput rate and thus, 7 % energy saving in specific energy consumption.

1 Introduction

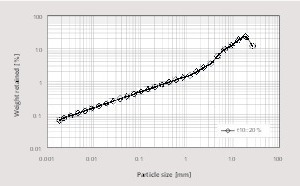

High pressure grinding roller (HPGR) crushers are used conventionally as a pre-crusher ahead of the ball mill to reduce the specific energy consumption of the grinding stage or to increase the grinding capacity of the circuit in cement grinding circuits [3, 4, 5]. A vertical shaft impactor (VSI) type crusher can also be used as a pre-crushing unit in cement grinding circuits to carry out an efficient grinding process. This type of application will reduce the total grinding energy requirement by increasing the grinding capacity. VSI type crushers have various advantages such as...