Engineering design of mechanical equipment for the production of cement on basis of configurators

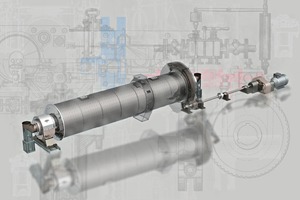

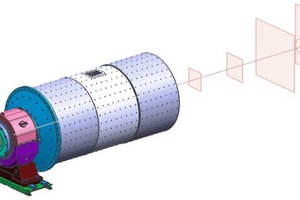

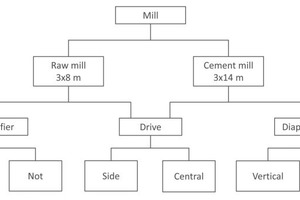

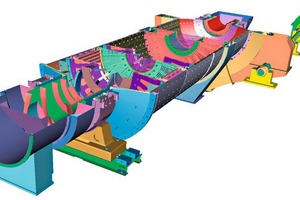

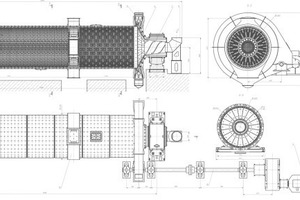

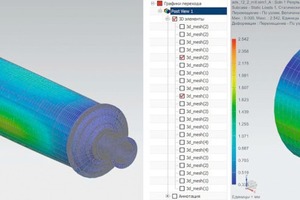

The Russian cement industry is an industry in growth. Supply of machines, apparatus and complete plants necessary for production must follow this development. This applies to quantity and quality. A key instrument in this context is order processing supported by the help of configurators. These configurators offer opportunities to ensure quality and simultaneously reduce processing times. The following contribution shows the possibilities of action considering ball mills.

1 Situation

The cement industry is a dynamically growing sector of Russian economy. Analysts estimate further positive prospects due to Russian infrastructure modernization and realization of the state house building program. This leads to corresponding refurbishment and new development of production plants involved. Influence on this present development is the target of a wide coverage of machinery demand by domestic suppliers. This involves several apparent aspects in comparison to established international suppliers:

Lower degree of automation, process control and operational performance,...