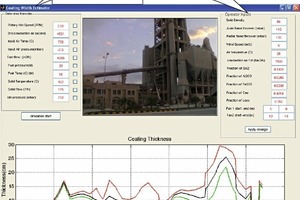

Estimation of coating thickness in a rotary kiln by using shell temperature and kiln modeling

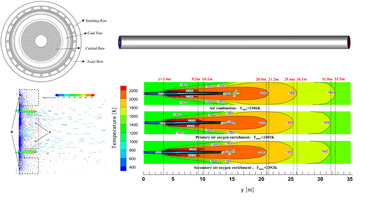

In a rotary kiln very versatile and complex processes take place that are strongly nonlinear and time dependent. Efficient protection of the coating in the sintering zone during kiln operation is an important problem from the standpoint of productivity of the kiln. The purpose of this study is to develop a computer program for evaluating the coating thickness in various sections of the kiln.

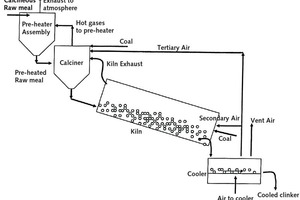

1 Introduction

Cemen...