Experiences and insights from an installation for secondary fuels

Every cement expert is aware of the difficulties the sector is experiencing and of the influence of the use of alternative fuels when it comes to reducing costs. With these premises, CPV Monjos requested the help of FLSmidth Pfister in the design of an alternative fuel facility back in 2009.

1 Introduction

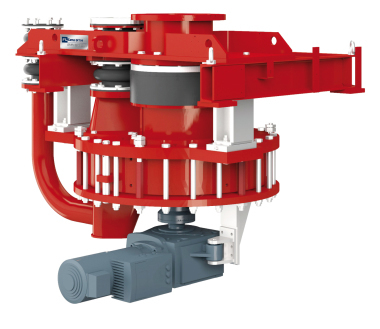

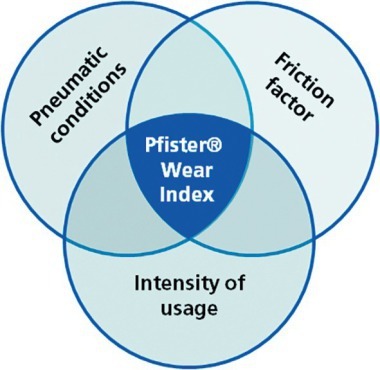

It has been quite a while since the cement industry began to use alternative fuels. We all remember when in 2001, with the mad cow crisis, cement plants were asked to burn animal meal for kiln firing. At that time, several plants in Spain adapted their facilities for dosing this material. But within a few years the amount of animal meal available on the market was significantly reduced. Lucky were those who employed multi-fuel dosing equipment from supplier FLSmidth Pfister. Their Pfister TRW-S rotor weighfeeders allow for dosing of varying types of alternative fuels, even in...