Investigations into the application of calcined clays as composite material in cement

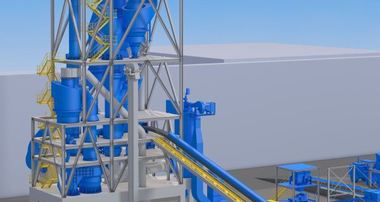

This article describes the successful use of the muffle kiln and the entrained-flow calcinator for the manufacturing of pozzolanas from clay raw materials, some of which were of very impure nature. Firstly, this demonstrated the suitability of cheap materials for this process, and secondly it tested the manufacturing of calcined clays by a process that is suitable for industrial scale application in composite cements.

1 Introduction

The Portland cement manufacturing process results in a high emission of climate-damaging carbon dioxide, primarily due to the decomposition of limestone as the main component of the raw meal used for the burning of cement clinker [1]. One efficient way of reducing these emissions is substitution of the clinker content in the cement by more environmentally-friendly but nevertheless effective composite materials. Apart from largely inert limestone, the only materials globally available for this purpose are hard-coal fly ash, which reacts like pozzolana (approx. 700 million tpa...