Latest trends in refractory materials

Today’s focus on cash flow generation in the cement industry leads to an over-simplification of the complexity of cement processes. One example is refractories, which are mostly regarded as commodities. In this article we will look at, what can be wrong with this approach.

1 Introduction

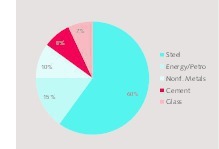

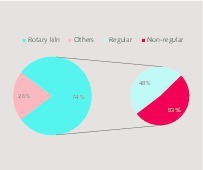

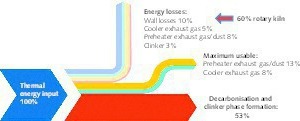

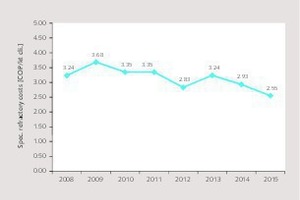

Refractories are indispensable for high temperature industrial processes. Their raw materials are minerals with high melting points, such as magnesite, dolomite and aluminum silicate. The global refractory market exceeds 20 € bn. Roughly 8 %, (1.6 € bn) is used by the cement industry (Figure 1). The largest consumer is the steel industry with 60 % (12 € bn), followed by energy/petrochemical industries with about 15 % (3 € bn) and nonferrous metals with 10 % (2 € bn). The glass industry comes close to the cement industry with 7 % (1.4 € bn). In modern precalciner systems...