Lignocellulosic biomass fermentation process co-product fuel for cement kiln

(22) 10.10.2014

(43) 17.08.2016

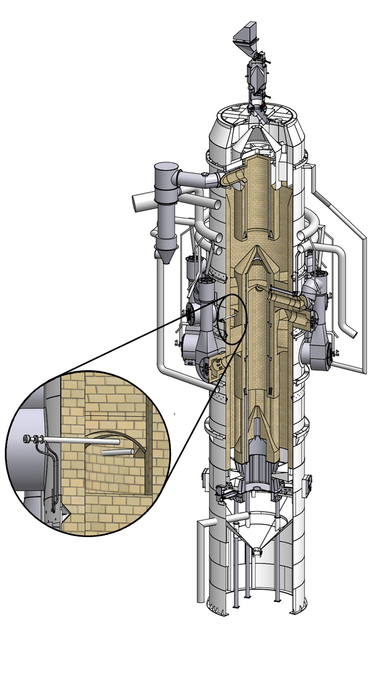

(57) Summary of corresponding patent US2015101511 (A1): A fuel made from co-products derived from a lignocellulosic biomass fermentation process is used to fuel a cement production process. Filter cake and syrup co-products are mixed and dried, then burned in a cement kiln to create the temperatures needed for cement production.

(73) E. I. du Pont de Nemours and Company (US)