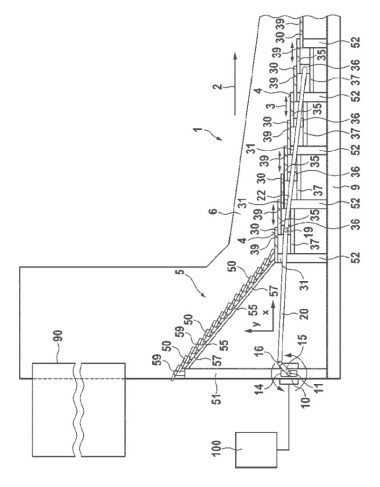

New IKN cooler for Argentina

In May 2014, Holcim (Argentina) S.A. placed an order for a state-of-the-art IKN Pendulum Cooler® with a grate area of 61 m2 and the latest Coanda Wing® technology, designed to replace the existing drum cooler at Puesto Viejo, Argentina. The new clinker cooler will be single stage with a single hydraulic cylinder drive located under the IKN Clinker Inlet Distribution System (KIDS®) including a Clinker Flow Optimiser (CFO) and an IKN Roll Crusher with four rolls at the cold end.

Included in the scope of IKN is a new pan conveyor to bridge the distance between the clinker discharge of the new cooler and the existing clinker conveyors plus a new electrostatic precipitator including dust emission control and the corresponding exhaust fan.