One-dimensional simulation method for predicting quality

of clinker in rotary cement kiln

(22) 11.11.2016

(43) 03.05.2018

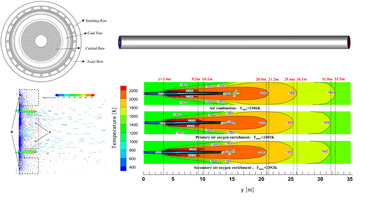

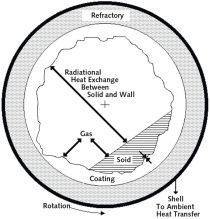

(57) A one-dimensional simulation method for predicting calcination quality of clinker in a rotary cement kiln, the method comprising: (1) acquiring relevant information concerning a rotary kiln, the clinker calcination quality of which is to be predicted; (2) establishing a one-dimensional mathematical model of the interior of the rotary cement kiln, which comprises a pulverized coal combustion model, a heat transfer model, a material bed movement model and a clinker mineral chemical reaction model; (3) acquiring data of the actual production of the rotary cement kiln as boundary conditions of the mathematical model; (4) calculating and obtaining, according to the one-dimensional mathematical model and the boundary conditions, changes in smoke temperature, material temperature, material bed height, wall temperature, material chemical composition and clinker mineral content in the rotary kiln as the length of the rotary kiln; (5) according to the simulation results in step (4), the predicted clinker quality being contents of f-CaO at a kiln outlet and C3S, C2S, C3A, and C4AF minerals, and optimizing and adjusting, according to the prediction results, the actual production operation.

(71) Zhejiang Bonyear Technology Co., Ltd (CN)