Open gear service and documentation by Fuchs Lubritech

Open gears in the cement industry are capital goods requiring very high investments. Regular service as part of the maintenance is the prerequisite for their reliable operation and long service life. It goes without saying that owners and operators want to keep track of their machines by means of service or even repair reports. An efficient reporting tool is thus required.

Service

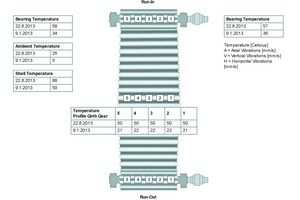

In order to maintain an open gear, its condition has to be checked at regular intervals. After an initial visual check the detailed inspection starts with the lubrication system. In the case of a spray system the spray pattern, spray quantity, and spray intervals are reviewed. Furthermore tooth flank temperatures, bearing housing temperatures, and mill/kiln shell temperatures are to be measured as are horizontal, vertical, and axial vibrations. Tooth flanks may also have to be gauged regarding their root clearance, backlash, thickness, and surface roughness. The gear alignment is to be verified, especially if a part of the gear has been replaced, e.g. new pinion with old girth gear. A crack and damage inspection is also required. In the event of damage, the gear has to be repaired, and its failure has to be analyzed to determine the root cause.

With a clearly arranged and easy-to-handle documentation system the customer not only receives general data on the current machine condition but also on trends and thus a possible future prospect.

Documentation

A service report should include customer information, gear data, photo and/or video documentation, results of the lubrication system check and all measurements, comments, trends, and other visual documentation such as infrared pictures. All data, previous and current reports, trend analyses and vibration recordings of a serviced gear should be accessible to the customer/operator as soon as possible. This means that the report has to be finished without delay, preferably on site. The ideal situation is that the customer has, for example, an App on a mobile device, either Android or iOS, and is notified of the new report which is then accessible immediately.

An example for such an intelligent reporting system is the FLT Inspector by Fuchs Lubritech. With this unique tool the service engineer enters all data into a tablet computer while inspecting the gear. Even pictures with an infrared camera or videos of the gear can be directly attached to the report (Figure 1). After finishing the new report a short message will be sent to those who are registered for the respective machine. The new report will then complement the documentation of all previous reports, which will of course remain in the system (Figure 2). All reports which can also be saved for offline access are available at all times (24/7) for the customer/operator, no matter if they use a smart phone, a tablet computer or a desktop computer.

A few words to the access right specifications. Access to machines or sites are transferrable and customizable. Some examples of customized access rights:

Responsible at a company’s headquarters ➝ access right to all international sites/machines

Plant/maintenance manager of a company’s plant ➝ access right to all machines in this plant

Kiln maintenance manager of a company’s plant ➝ access right to all kilns in this plant

This way only those people having a specific interest in a machine receive messages on this machine. To satisfy the international market any information should be available in more than one language. In Fuchs Lubritech’s case the reporting system is currently available in nine languages (Chinese, English, Farsi, French, German, Japanese, Portuguese, Russian, and Spanish).

//www.fuchs-lubritech.com" target="_blank" >www.fuchs-lubritech.com:www.fuchs-lubritech.com