Rotary valves have always been used for discharging and volumetric feeding powdery or granular materials from silos, hoppers, filters or cyclones. WAM® offers high-quality, market-oriented rotary valve concepts for feeding bulk materials within continuous mixing and processing systems. These valves are suitable for use with fine powders, such as cement or lime, or granular materials, virtually in every field of application.

Rotary valve types and design

features

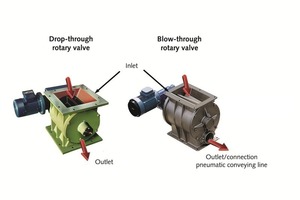

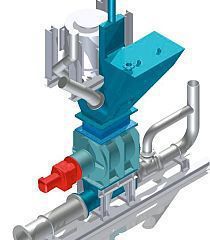

First of all, the selection of the appropriate type of rotary valve depends on the type of conveying system in which the unit is supposed to be integrated. So-called drop-through rotary valves are installed beneath storage silos. The material is transferred from the silo via an inlet into the rotor pockets, before it vertically drops through the outlet at the bottom into a downstream unit (e.g. a screw conveyor) due to the rotation of the valve rotor and gravity. In case of pneumatic conveying systems, blow-through rotary valves are used (Fig. 1). This type of valve is connected to a pneumatic conveying line. In this case, the material handled is either sucked from the rotor pockets or blown into the conveying line.

The selection of the correct rotary valve and of its drive and accessories depends on various important criteria:

Type of material properties such as bulk density, grain size, abrasiveness, flow-ability etc.

Material moisture and temperature

Required volumetric throughput (cubic metres per hour or litres per revolution)

Operational capability of the rotary valve as drop-through or blow-through rotary valve (to determine the range of revolutions)

Time of operation per day or number of start-stop intervals per hour

Required safety certification such as explosion protection (ATEX)

The loading of the rotor pockets depends on the flowability of the material and on the velocity of rotation of the rotary valve. In other words, the lower the flowability of the material, the lower the velocity of rotation to achieve an optimum loading of the rotor pockets. Another important aspect for the design of a rotary valve is the abrasiveness of the bulk material. Low speed means less wear and tear. Therefore, for highly abrasive materials rotary valves with a large volume and low speed are recommended.

Four model series for the

building materials industry

WAM® offers three types of drop-through rotary valves (RV, RVR and RVC) which are used to feed powdery materials (Fig. 2). The feeding capacity of these rotary valves is from 0.3 up to 55 m³/h with a standard rotor speed of 10, 20 or 30 rpm. As regards the versions with mechanically variable speed drive, the speed of the rotary valve can be adjusted manually or via an electric pulse in such a way that the product is fed into the process exactly in the pre-established quantity. As an alternative, fixed drives may be speed-controlled by a frequency converter.

The RVS type is a blow-through rotary valve from the WAM® range which enables accurate feeding into a pneumatic conveying process.

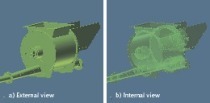

In addition to the many possibilities of application, WAM® rotary valves are particularly distinguished by their rugged, compact design and small footprint.

Versatility thanks to optional

accessories

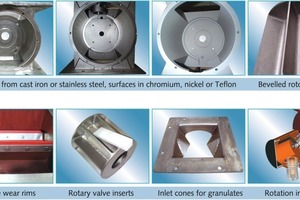

With a variety of possible applications and vast material properties, the key to adaptability is the selection of optional accessories (Fig. 3). WAM® is flexible as regards individual requirements and offers a comprehensive range of accessories for each series of rotary valves:

Casing and rotor manufactured from different materials: grey cast iron or special steel, as well as surface treatment with chromium, nickel or Teflon®

Rotor with anti-wear strips made of spring steel, Vulkollan®, Teflon® or special steel to improve sealing and reduce abrasion

Rotor with bevelled blades

Rotor pocket inserts for caking bulk materials

Alternative drive options: direct drives with constant or variable speed, coaxial drives with chain transmission, various electric motors, versions with a bare shaft

Rotation monitoring indicator

Explosion protection: ATEX Zone 22