FLSmidth has signed a licensing agreement with Wasabi Energy for its Kalina Cycle® technology

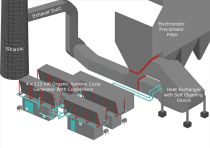

The Kalina Cycle technology is able to recover waste heat from industrial process gas streams and convert the waste heat to usable electrical energy. It is one of the most efficient waste-heat-to-power systems on the market and with the licensing agreement FLSmidth obtains exclusive rights to offer this technology to the cement and lime manufacturing industry globally, except in very few countries where licenses have already been issued. The license agreement enables FLSmidth to offer customers a unique waste heat recovery system which will lower plant operating costs and reduce CO2 emissions and water consumption at an attractive investment level. The patented ammonia water process of the Kalina Cycle provides efficiencies 10–50 % greater than other conventional technologies. In January 2011, FLSmidth signed its first contract with Wasabi Energy to build the world‘s largest Kalina Cycle power plant at the D.G.Khan Cement Company, Khairpur Plant in Pakistan. The delivery is on schedule and FLSmidth has already identified numerous other potential cement plants suitable for the immediate application of the Kalina Cycle waste-heat-to-power generation technology.