Nord components increase the energy

efficiency of drive systems

Not only in times of rising energy prices is energy efficiency one of the most important goals of industry. Highly efficient components from Nord Drivesystems help to reduce the energy consumption of drive systems. Additionally, the drive specialist offers its customers energy-related advice.

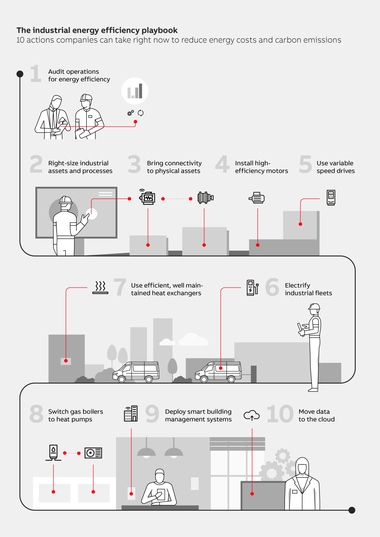

The company’s drive components are increasingly optimised towards the factor of energy efficiency. A study by the Mechanical Engineering Industry Association VDMA and the management consultancy Boston Consulting Group has shown that innovative technologies in mechanical engineering and plant construction can help to reduce CO2 emissions in the entire industry by up to 86%.

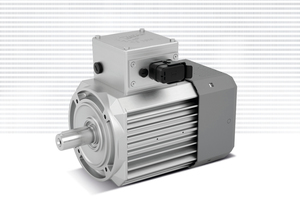

Highly efficient IE5+ synchronous motor

Nord sets new standards with regard to energy efficiency with the IE5+ synchronous motor, which achieves an efficiency of up to 95%. Thanks to permanent magnet synchronous motor technology (PMSM), it achieves this high efficiency relatively constantly over a wide speed and torque range and also provides very good energy consumption performance in partial load and partial speed ranges. This means that it even surpasses the highest defined energy efficiency class IE5.

Due to its wide power range, the IE5+ also contributes to reducing the Total Cost of Ownership (TCO) beyond the energy efficiency by enabling version reduction in an overall system.

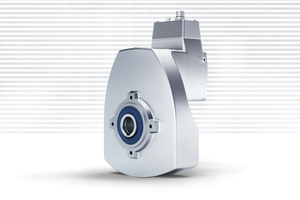

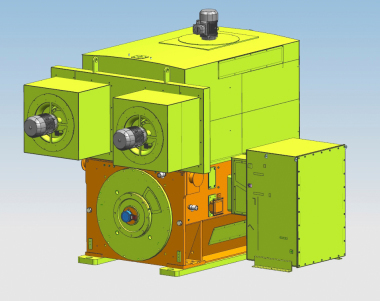

Patented DuoDrive geared motor

The IE5+ synchronous motor is also part of the patented DuoDrive geared motor, where it has been integrated into a single-stage helical gear unit. Calculated via the system, the geared motor achieves up to 92%, one of the highest efficiencies on the market in this power class. The integration of the drive into the gear unit housing reduces the installation space, the number of wear-prone parts and thus also the maintenance effort. The elimination of component joints also greatly minimises the risk of liquid ingress and bacterial contamination.

The DuoDrive was specifically developed for intralogistics and the food industry. In an application for the beverage industry, Nord also conducted an energy efficiency investigation. In an exhibition model, where bottles are conveyed in two circular systems, the drive specialist compared the power consumption of two drive configurations: first, a DuoDrive including a Nordac Pro SK 500E control cabinet frequency inverter and the other a customary IE3 asynchronous motor with bevel gear unit and decentralised frequency inverter. The result: The DuoDrive consumes up to 50% less energy.

Reducing the carbon footprint

Nord Drivesystems not only helps its customers to discover and achieve such a savings potential with its efficient components but also with a special service. The Nord Eco service checks the customer’s installed drives with regard to energy efficiency, dimensioning and number of versions. From this, Nord creates an energy efficiency concept that identifies possible savings potentials and is tailored to the customer’s requirements.

As a committed family business, Nord Drive-systems also attaches great importance to reducing its ecological footprint in the interests of inter-generational justice and the fight against climate change.