New series: Vacuum blowers with hermetic drive

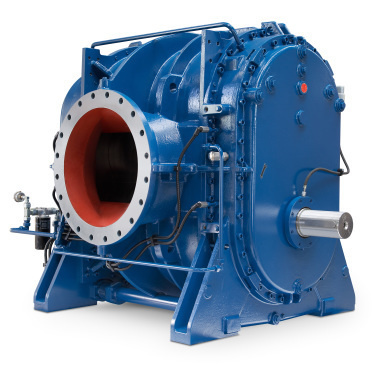

Aerzener Maschinenfabrik GmbH has manufactured Roots blowers since 1868 and is one of the oldest and largest manufacturers worldwide and has a leading market position in Europe. Especially in the field of vacuum technology Aerzen can look back on more than 60 years of experience. Based on the successful blowers with canned motor drive for aggressive gases in the solar- and semiconductor technology, Aerzener Maschinenfabrik has now extended the relevant kit by new hermetic drives for the industrial application with non-aggressive gases (Fig.).

The first sizes available are the types GM 8000 HM and GM 9500 HM for volume flows in the range of 8000 m³/h to 15 300 m³/h at speeds of 50 c/s and 60 c/s. Thanks to the hermetic design a vacuum of 10-5 mbar (abs.) can be obtained. Further sizes in the medium volume flow range from 2000 m³/h to 7500 m³/h will probably come onto the market in summer 2009, so that a total of 7 machine sizes can then be offered. As the new drives are also water-cooled and equipped with a novel canned motor, the energy efficiency of the motors can be increased by up to 30 %. Due to the hermetic motor the shaft passage to atmosphere can be omitted, therefore, possible oil leakages belong to the past. At the same time, the speeds can be increased by means of frequency converter operation of up to 120 c/s, i.e. smaller machines obtain a higher volume flow. Considerable advantages in costs and possibilities for reduction of the installation dimensions are obvious. Depending on the type of process three different motor variants may be applied: For continuous operation (process application) motors with a maximum load of 70 mbar are available, for cyclic operation (load lock application) motors are used which have a load of up to 250 mbar, so that shorter pumping periods can be accomplished. In addition, system motors for 50 resp. 60 c/s can also be applied.

The main advantages of the new vacuum blowers are the optimum selection possibilities by the world’s largest canned motor series as well as by 3 additional motor variants. The customer can select from a substantial modular construction system the optimal blower-motor type for his application. Consequently, machines are available for the application with non-aggressive gases (PVD) and for aggressive gases (CVD) as well as with various motor types for process- or load lock operation respectively.

In addition, Aerzen blowers are distinguished from all others by a high mechanical load (up to 250 mbar) making possible a considerable decrease of pumping-out periods. The water cooling of the motor of Aerzen canned blowers also guarantees the application under clean-room conditions. Furthermore, the vacuum blowers are type-tested and certified for ATEX-zone 0 (internal).