Less residual moisture

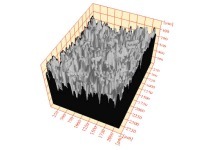

With Vacubelt® 2015 (Fig. 1) the business unit WEAVEinMotion

of GKD – Gebr. Kufferath AG proudly presents a new generation of filter media for vacuum belt filters. „We have significantly improved the belt types 2025 und 2035 that are used with great success in gypsum filtration after flue gas desulphurisation,“ explains Kurt Widdau, the business unit manager. The crucial new feature is that Type 2015 is made purely of polyester monofilaments and no longer with additional multifilament weft wires (Type 2035) or staple fibers (Type 2025). Multifilament mesh may block up in the fibers, causing a drop in the filtration rate. In contrast, the pure monofilament Vacubelt® 2015 supplies a consistently good filtration rate

(Fig. 2). Furthermore, thanks to its smooth surface its cleaning capabilities are also even better.

This good filtration performance has been confirmed by laboratory tests which document a residual moisture content of < 10 %. By means of a special mesh construction, GKD has managed to even further increase the number of pores per square meter. This means that, in spite of the small mesh aperture size – Vacubelt® 2015 has only 50 – 60 μm – air permeability is greater than for example in the case of the previous vacuum belt filter types 2025 or 2035. The result: even faster dewatering at a constant filtration rate.