Understand processes – optimize processes

Seminar, Aachen/Germany (14.10.2009)On 14.10.2009 a seminar took place dealing with the topic of process optimization in the cement industry. 3e consult in cooperation with the engineering office aixprocess had invited experts from cement manufacturers and plant builders to come to Aachen to discuss possibilities to optimize the process of cement making.

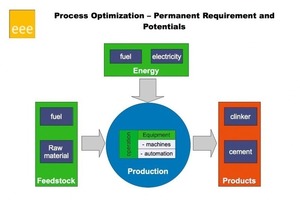

The cement industry has made good progress in the fields of environmental protection, energy efficiency and fuel substitution for decades. In order to meet the continuously increasing environmental requirements as well as the permanent pressure of costs, today it is often necessary to even further optimize the processes in spite of the high level already reached. In trying to do so, the experience was gathered many times, that further improvements are hard to reach. Actually, further optimizations are only possible if the production process is basically understood in the complexity of the interaction of all its components, i.e. raw materials, fuel, plant technology and operation (Fig. 1). For instance, the mutual influences between lumpy secondary fuels and the flow behaviour inside a calciner as well as its feedback effect on the burn-out and precalcination must be investigated so that in turn it may be incorporated into the configuration and operation of a calciner.

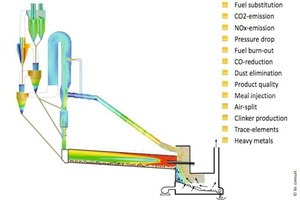

To investigate and optimize these and similar processes, modern numerical engineering tools are available (Fig. 2). Thermochemical simulations and computational fluid dynamics offer possibilities to analyze chemical and physical processes going far beyond conventional methods. The possibilities of modelling and computation have been significantly further developed in the last few years essentially increasing the applicability and reliability of this method. Today, for example, a CFD code is available, which for the first time maps the interactions between dust particles and the surrounding gas in a bidirectional closed way. Thus, the calculation of multiphase flows with dust loads, which are typical in a cement plant, has considerably come nearer to a quantitative evaluability. Based on work dependencies investigated this way, optimization solutions can be developed which are effective “from the root”.

The participants at the seminar acquired knowledge covering these new possibilities of computation and discussed their fields of applications and limits. To elucidate the practical importance for the cement industry, the participants discussed a specific example within the framework of a workshop: What is the effect of the addition of oxygen on the combustion of secondary fuels in the kiln flame, and how should this addition of oxygen be optimally configured so as to be able to use as much secondary fuel as possible?

After a long day of intensive discussions, they said goodbye to the participants who went home with many ideas for the implementation of what they had learned.