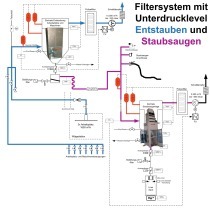

Filter systems for gypsum production

Architects, building planners and craftsmen value gypsum for its versatility as a material, in particular. In addition to its use in filigree stucco and moulding work, modern building practices are also characterized by the use of prefabricated gypsum el- ements. Numerous gypsum grades, and products such as gypsum finishing plasters and wallboards, permit a broad range of applications.

The making of these gypsum products generates very large quantities of dust, and dust removal (“dedusting”) arrangements during the production process are vitally necessary to protect employees, machinery and...