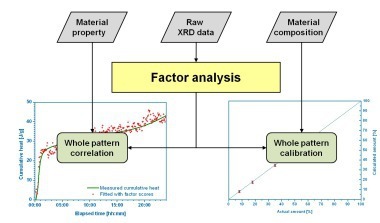

Dr. Rietveld in the Karlstadt cement plant

On 14th September 2009 Schwenk Zement KG welcomed Dr. Hugo M. Rietveld and his family to the Karlstadt cement works. Though the method for the evaluation of X-ray powder diffractograms in the cement industry developed by Dr. Rietveld is widespread in the meantime, it was the first time that he could be welcomed as a guest at a cement factory. The plant tour including a supporting program organized by Schwenk Zement KG and PANalytical BV within the framework of the workshop “Building Materials Analysis, 2009” in Halle was a very interesting and informative event for the Rietveld family and all participants where the requirements for modern cement production could be impressively demonstrated. In the afternoon Dr. Rietveld described his personal background and his research work. The audience could listen to the history of how the Rietveld method came into being at first hand.