S.S.T. Schüttguttechnik GmbH

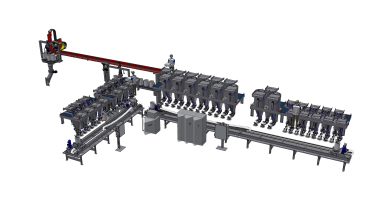

S.S.T is introducing onto the German market a new brand of gravimetric micro feeders and powdering machines under the brand name MCPI Fine dosing. Thanks to an exclusive principle of extraction, highly developed, the “Fine dosing” system sets new standards in precision, speed and user-friendly operation (Fig.). The product is dosed in a small swivelling bowl fitted onto an accurate load cell. Sensitive parts such as drive and scale are protected in a stainless steel housing. At the end of dosing stage, the bowl is emptied by rotating it 180 °. The integrated batch controller optimizes coarse and fine feeding with automatic tolerance control. The fine dosing concept allows permits a coarse/ fine dosing ratio of 1/50.

Hall 7, Stand 7-140

www.solids.de