10-m Filter Bags

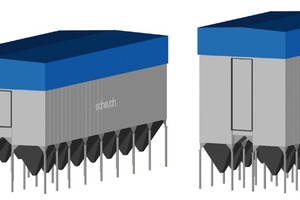

In 2009, in the course of additional and intensive R&D efforts Scheuch was also able to transfer the previous advantages of EMC technology (Fig.) to applications using 10-m filter bags and verify these advantages in actual practice. Based on convincing long-term testing using representative dust types and filter media for cement grinding plants and kiln dedusting systems, as well as comparative measurements using different bag lengths, it was possible to confirm a virtually identical filtration behaviour as the basis for sufficient operating reliability. Holcim (Deutschland) AG was the first customer to order from Scheuch an EMC filtration plant equipped with 10-m filter bags for the planned conversion of the kiln dedusting system at its plant in Lägerdorf. The main advantage associated with longer filter bag lengths is primarily the clearly lower investment costs, which are the result of the compact design and a weight reduction of up to 30 % – compare EMC 6-meter: EMC 10-meter. In addition, applications using 10-meter filter bags require only half of the installation space compared to those using the 6-meter filter variant.