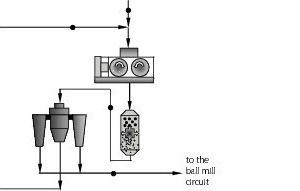

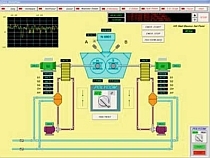

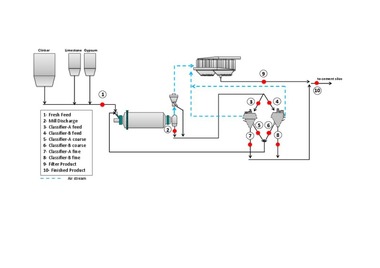

Circuit high pressure grinding rolls (HPGR) in a cement grinding plant

Part 1: Evaluation of overall performance

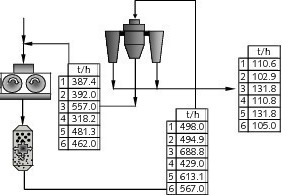

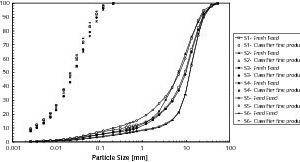

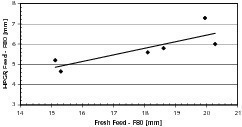

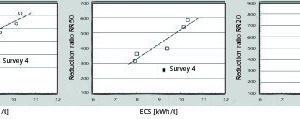

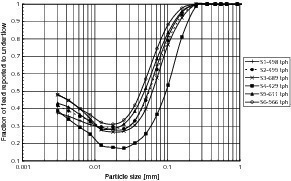

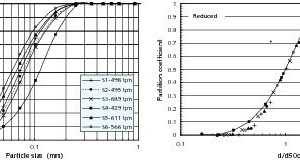

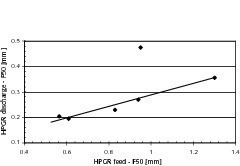

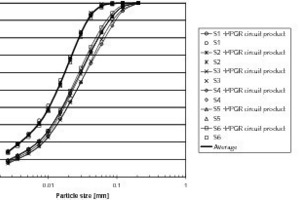

Summary: In this paper, the performance of a closed circuit HPGR operation was evaluated by the data obtained from six measurements in a cement grinding circuit operating in Turkey. Flowrates of the streams and classifier performance were evaluated after mass balancing. The average specific energy consumption of the HPGR for six measurements was 9.62 kWh/t for grinding from 17.9 mm to 57 µm (80 % passing size). Reduction ratio increased with the increase in specific energy consumption. Although cut point and the bypass of the classifier varied in a rather wide range, reduced efficiency curve and imperfection values indicated that the sharpness of separation remained the same.

Since their first application in 1985, HPGRs have been increasingly used in cement grinding circuits [1]. They have now stood the test in terms of capacity and energy efficiency increase in comparison to ball mill-air classifier circuits. Their success in the cement industry has attracted the attention of the mineral industry and the number of applications has been increasing rapidly [2–9].

Despite progress in technology and applications, relatively few data regarding operating plants have been published. In cement grinding, it was shown that more could be achieved when a larger...