Innovative, energy-efficient manufacture of cement by means of controlled mineral formation – Part 1

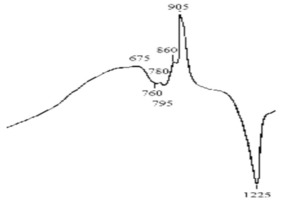

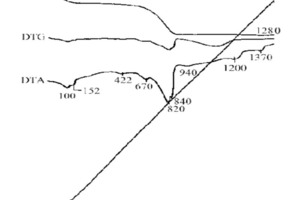

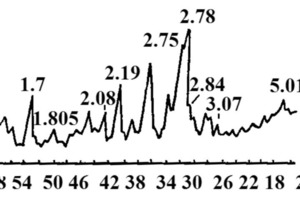

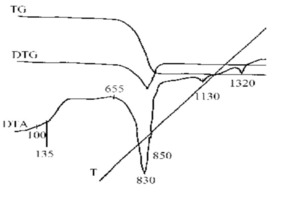

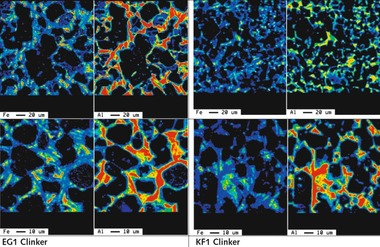

Summary: The mechanism of the formation of alite and belite with extremely coarse raw mixes may proceed kinetically more energy-efficient according to investigations using ESMA, DTA and XRD via three models. According to model 1 the reaction takes place due to the crystallization of the melt rich in SiO2 diluted with easily melting phases. Model 2 starts from centres supersaturated with CaO, which are used as crystal nuclei and crystallization centres for the formation of alite and belite and that are originated at the reaction interface between the melt rich in SiO2 and the aggregates of the solid phase of CaO. Model 3 refers to the absorption of the melt rich in SiO2 by the conventional melt. The alite formation is completed via the conventional melt.

Cement making is a very energy-intensive process. The overall energy costs result from the consumption of electric energy and fuel energy of approximately equal parts. In spite of the achieved reduction in heat consumption down to approximately 3000 to 3200 kJ needed to burn 1 kg of clinker, the theoretical heat consumption with about 1600 kJ is still significantly lower. However, the efficiency of approx. 50% thus achieved, which is extraordinarily favourable for technical burning processes, still involves a lot of reserves to further save fuel. The total consumption of electric...