Near-infrared (NIR) on-line analysis for

coarse-grained raw materials

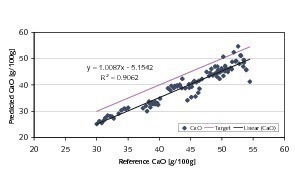

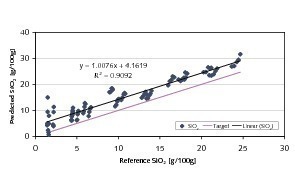

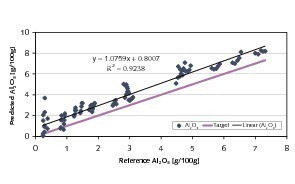

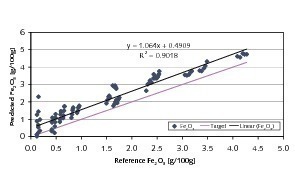

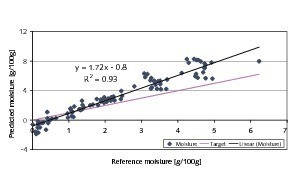

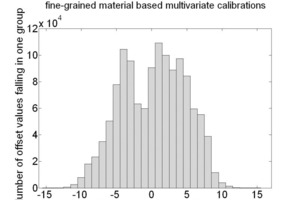

Summary: In the present paper the use of near-infrared (NIR) spectroscopy for predicting the concentration of CaO, SiO2, Al2O3, Fe2O3, as well as the moisture content of cement raw material on line is evaluated. Two sets of near-infrared spectra were used to assess the effect of systematic changes in the particle size fraction on the predictive performance. The results of this study promote the applicability of using fine-grained bore-hole samples of a raw material quarry as base calibration and the transfer of this calibration for on-line analysis of coarse-grained raw material as delivered by a primary crusher.

The near-infrared (NIR) region of the electromagnetic spectrum extends from 780 nm to 2500 nm (wavelength) or 12 800 cm-1 to 4000 cm-1 if measuring in wave numbers (the number of waves per cm). NIR spectroscopy is concerned with absorptions of NIR energy by molecules within a sample. Absorptions are caused by different mechanisms: fundamental vibrations, overtones of fundamental vibrations, combinations of fundamental vibrations, as well as electronic absorptions [1-3]. Overtones are approximate multiples of the fundamental vibrations. The vast majority of fundamental vibrations...