Trends in power generation from waste heat in cement plants

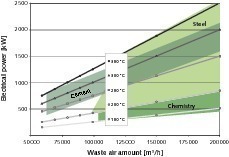

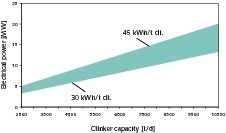

Summary: The generation of power from waste heat in cement plants was for a long time the subject of controversial discussion. Today, hardly anyone remains unconvinced by the concept. Depending on the system used, 30–45 kWh/tclinker can be generated, which is up to 30 % of the electrical power requirement of a cement plant. The benefits of this technology are clear. As electricity and energy costs increase, the plants become more and more cost-effective and the CO2 emission situation provides additional incentive. This report presents an overview of the technology and system vendors, indicates the reference systems and describes the market prospects.

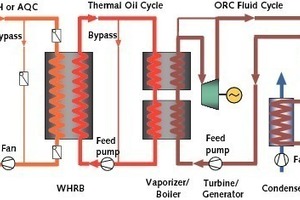

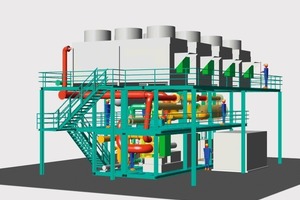

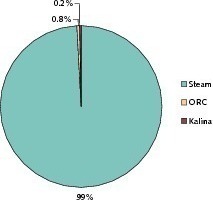

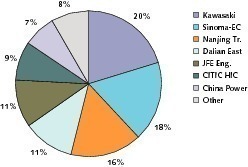

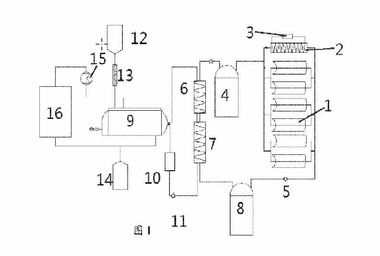

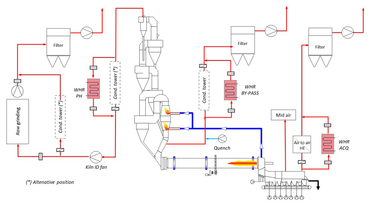

Japanese companies spearheaded the introduction of Waste Heat Recovery systems (WHR) in the cement industry. In 1980, Kawasaki Heavy Industries (KHI) put a WHR system into operation at Sumitomo Osaka Cement [1]. The first major system, with a capacity of 15 MW, has been in operation since 1982 at Taiheiyo Cement’s Kumagaya plant (Fig. 1). This system consists of waste heat boilers for kiln and cooler exhaust air with a conventional steam circuit and subsequent steam turbine for the power generation. HeidelbergCement took a different approach. In 1999, they put the cement...