Low temperature drying: a case study

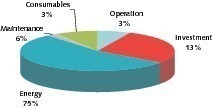

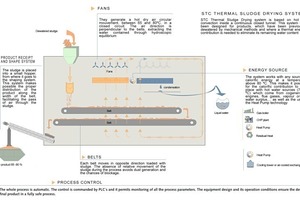

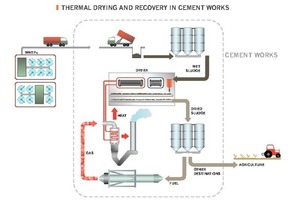

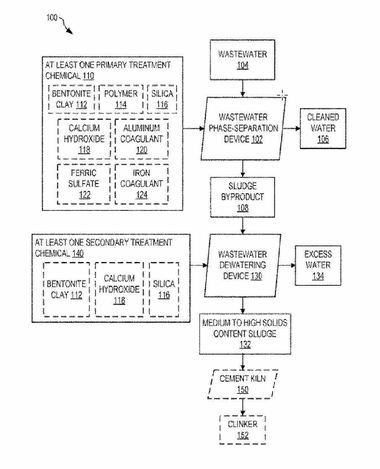

Incorporating waste treatment processes in systems in which residual energy can be utilized is one of the best residue management alternatives. With an LHV of between 2000 and 4500 kcal/kg, efficiently dried sewage sludge can be used as standard fuel, thereby reducing primary energy consumption and the CO2 quota.