Increase of V-separator efficiency

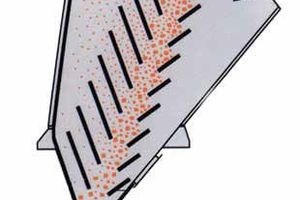

The V-separator has been widely adopted for processing of comminuted material, mainly for closed circuit systems with roller press. It is a really static and energy-saving apparatus that has high reliability in operation. It also carries out the function of disaggregation of material cakes after compacting by the roll. The cakes fall down by the slanted step grate of the separator. They are then divided into parts and scavenged by transversal airflow. Small parts are carried by flow to the top separator output and the coarse parts fall down and return back to repeat destruction.

However, the...