ABB brings AI to asset performance management

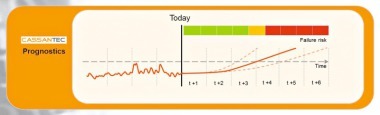

ABB has strengthened its existing digital offerings with the launch of the ABB Ability Genix Asset Performance Management (APM) Suite for condition monitoring, predictive maintenance and 360-degree asset performance insights for the process, utility and transportation industries.

The Genix APM Suite makes it easy to add asset condition monitoring to existing operational technology (OT) landscapes, enables prioritization of maintenance activities based on AI-informed predictions, and provides a comprehensive overview of asset performance.

The Genix APM Suite also empowers significant improvements in operational sustainability. By assessing the remaining useful life of industrial assets, Genix APM generates a plan for preventive maintenance, which can extend equipment uptime by as much as 50% and increase asset life by up to 40%1.

With reliable data insights, decision makers are provided with the information required in order to identify gaps and areas of improvement for energy efficiency and tighter control of operations, increasing asset availability and improving profit potential.

“Poor asset availability and reliability is a major problem that results in unplanned downtime and unexpected maintenance costs, and also impedes strategic planning and procurement,” said Rajesh Ramachandran, Chief Digital Officer at ABB Process Automation. “It’s not that industrial customers lack data; it’s that many lack effective ways to use their data to improve operational and business performance.”

Genix APM is built on the ABB Ability™ Genix Industrial Analytics and AI Suite. ABB Ability Genix is a modular, IIoT and analytics suite, which integrates IT, OT and other enterprise data in a contextualized manner, applying advanced industrial AI capabilities that support new insights to optimize operations.