A simple sampling method for VRMs

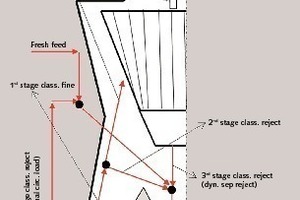

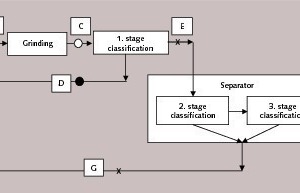

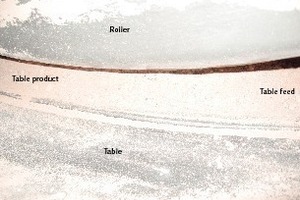

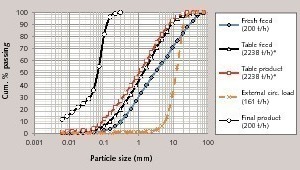

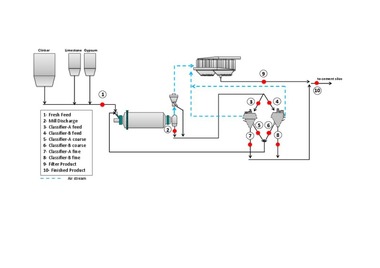

Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the mill casing. This situation leads to sampling problems around the equipment. This paper discusses a new simple sampling technique used for VRM in order to evaluate the performance of grinding and classification units, separately.

1 Introduction

Because of the low specific energy consumption and simple compact design of vertical roller mills, their usage is becoming widespread in the cement industry for finish grinding of cement raw material, coal and clinker. Today, in order to produce the final product, dynamic air-classifiers are built on the top of vertical roller mills, evolving from the edge (Brundiek, 1989), and to reduce the high power consumption caused by the internal pneumatic material transportation, this system has been entirely or partially replaced by the external mechanical recirculation system (Feige,...