About the sulfate resistance of slag composites

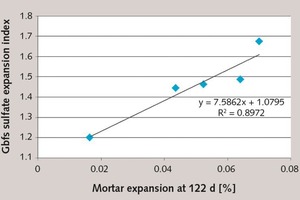

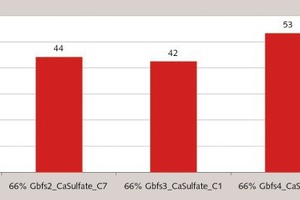

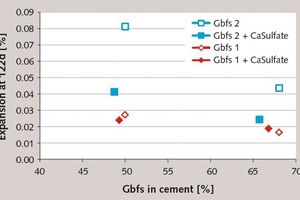

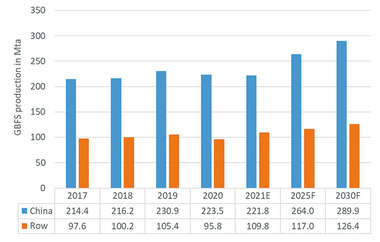

In Europe it is generally accepted that more than 65 % of granulated blast-furnace slag (GBFS) in composite cements make them high sulfate resistant. Proven by numerous studies, this rule has been implemented into national standards, such as the German DIN 1045-2. Due to the mechanism of sulfate attack, the composition of both, Portland clinker and GBFS influence the sulfate resistance of their composites, apart from an adequate cement and concrete design. In this study, mortars containing GBFS of different composition and high C3 A Portland cement were lab-tested for sulfate resistance. The results illustrate the influence of the alumina content of the GBFS, coupled with its reactivity, on expansion under sulfate attack. A GBFS Sulfate Expansion Index (GSEI) is proposed for rough indication, if a GBFS of given quality would need special attention when used in high sulfate resistant cements. Furthermore it was shown, that Ca-sulfate additions are very effective to increase the sulfate resistance of medium to high alumina GBFS-Portland composites.

1 Background

When sulfates in dissolved form, such as sodium, potassium, magnesium or calcium sulfates from soil or groundwater, enter hardened concrete, they react with the hydrated cement paste. Attacking alkali sulfates react with portlandite to calcium sulfate and sodium hydroxide. In the presence of calcium aluminate, the calcium sulfate reacts to ettringite. This reaction is coupled with a volume increase and pressure buildup, which can result in concrete cracking. According to Kunther (2012), sulfate expansion occurs when first, the pore solution is supersaturated with respect to...