Aerzen develops innovative modular system for large blowers

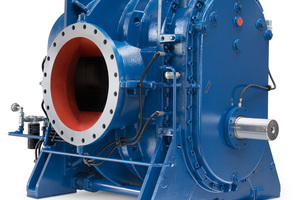

Aerzen large blowers are positive displacement blowers which can be applied virtually anywhere, convincing users worldwide by their quality, reliability and performance. These blowers reach volume flows of up to 77000 m³/h at a maximum overpressure of 1000 mbar and a maximum negative pressure of -800 mbar. This blower series is ideal for demanding ranges and applications. These blowers are used for the production of gases and oxygen or in the cement, foodstuff and chemical industry for pneumatic conveyance of bulk material.

With the Alpha Blower Aerzen wants to raise the proven concept to a new level of efficiency and flexibility. A type variation of 26 machines with only four different profile sizes due to the length modification of the cylinder is available. Furthermore, customers can select from a range of two and three-lobe rotors, as well as horizontal and vertical conveying directions, depending on the field of application and installation site. This increases the variety of models of Alpha Blower to 104 variants in total. The Alpha Blower proves to be particularly innovative with regard to measures for reducing pipe sound emissions: In the case of three-lobe blowers, the proven technology of interference channels for pulsation attenuation is still used, whereby the outlet contour of the two-lobe version is designed completely anew. By the use of the multi-flow principle for reducing air turbulences via an integrated soft inlet, which reduces pulsations, the pipe sound can be significantly decreased. Thanks to the new AirSilence technology, even downstream silencers can be of smaller dimensions now. AirSilence works according to the principle of attenuation of differential pressure. Due to supercharging in the conveying chamber, the pressure is increased and the differential pressure is artificially reduced towards the system side.

//www.aerzen.com" target="_blank" >www.aerzen.com:www.aerzen.com