Alternative fuel, preferably for production of portland cement clinker and method for processing and bagging as well as

application of this alternative fuel

(22) 01.09.2016

(43) 12.03.2018

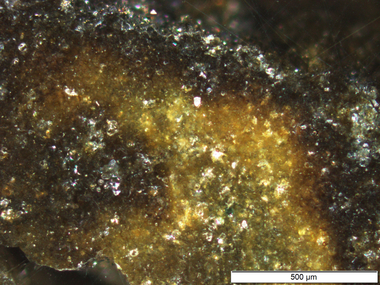

(57) Alternative fuel, in particular for the production of Portland cement clinker, is characterized by the fact that it is a post-flotation material from the process of enriching raw hard coal, the majority of which – preferably about 80 % – is a fraction with a grain size of less than 0.5 mm, with uniform consistency and ready-made after separating the process water into cartridges of a given energy value, optionally in stable and water-resistant, preferably vapor-permeable casings, wherein the single cartridge has a mass of up to 25 kg and/or its energy value is up to 125 MJ/kg, and durable and waterproof casings of individual cartridges They are made of natural and/or synthetic thermoplastic polymer materials, from paraffin paper or other products of the cellulose industry, or from fabrics or knitted fabrics, preferably impregnated. The application also covers the processing and packaging of alternative fuels, in particular for the production of Portland cement clinker, characterized by the fact that after homogenisation of the post-flotation fraction from the process of enriching raw hard coal, with a grain size below 0.5 mm and after drainage of process water returned to flotation , paste-like mass is taken from the filter press and subjected to forming into cartridges with a given energy value and/or mass and the produced cartridges are protected against demoulding.

The above defined alternative fuel produced by the method according to the application finds application in the Portland cement clinker burning process, as an energy and mineral charge in the synthetic aggregate production process and even in explosive mixtures, in particular for loads of rock explosives – intended for use in open areas, in a mixture with explosive materials, having a positive oxygen balance and/or with oxidants, such as nitrate and/or perchlorate, preferably ammonium and/or sodium and/or potassium and/or calcium, preferably containing gelling agents, such as starch, “guar gum” and the like, and also preferably containing an addition of aluminum dust.

(71) Explo Solution Spółka z Ograniczoną Odpowiedzialnością (PL)