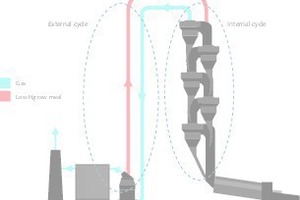

Breaking the mercury cycle for emission abatement with the “ExMercury – Splitted Preheater System”

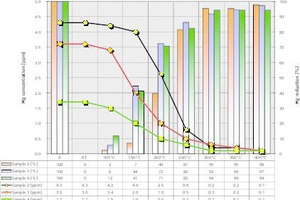

Due to the current trend of maximizing the substitution rates of alternative fuels, whilst emission regulations are being made more restrictive, the cement industry is facing a new challenge with minimization of a special pollutant. Mercury emissions have been identified as being caused by alternative fuels or contaminated raw materials and require an abatement system downstream of the pyroprocess. With the new ExMercury system, the consortium of A TEC, W&P Zement and Scheuch, has set up an effective solution combining a high emission reduction of up to 80 % with minimized operating and investment costs. This article also reviews briefly the basic mechanisms of the formation and reduction of Hg in the pyroprocess.

1 Introduction

The reduction of anthropogenic mercury emissions is of great interest, especially since it was agreed at the Minamata convention in 2013 which provided a basis for a worldwide reduction of mercury emissions [1]. Mercury is classified as a pollutant due to its toxicity and due to its physical properties as it forms a cycle in the atmosphere, leads to bioaccumulation and therefore enters the food chain. Therefore the focus is set on a limitation in the emission of this element.

The cement industry has been identified as second largest gaseous emission source of mercury just behind...

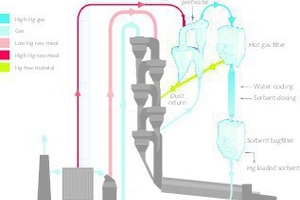

![2 Mercury pathways in the cement production pyroprocess [15]](https://www.zkg.de/imgs/tok_3070378eb41692381cb18cccd70711e6/w300_h200_x400_y243_101547300_f4fec5cf75.jpg)