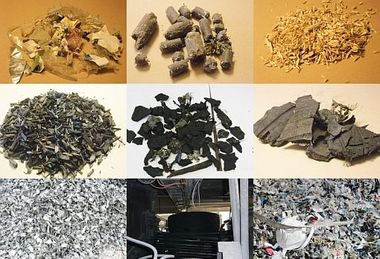

Burn-out characteristics of lumpy

secondary fuels and requirements for the design of calciners in the cement industry

A productive procedure for characterizing the pneumatic and combustion behaviour of lumpy secondary fuels is described. This can be used for calculating realistic flow and combustion processes.

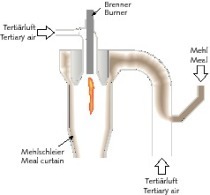

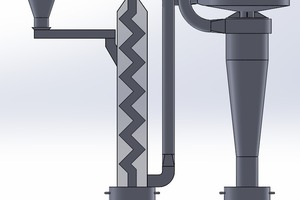

1 Conventional design of calciners in the cement industry

Calciners were introduced into the thermal lines for producing cement clinker in the second half of the last century and have brought about a substantial advance in technology for the cement industry, resulting in significant increases in performance of the kiln lines [1]. Since then many improvements have been proposed for this technology and implemented in product innovations [2-6].

As already described in [7] the fundamental idea behind calciner technology is based on the finding that the most energy-intensive process step in the...

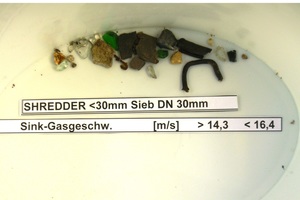

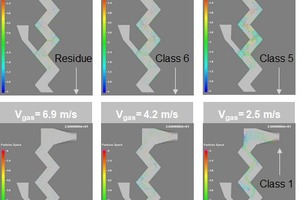

Gas velocity in the separator [m/s]](https://www.zkg.de/imgs/1/4/6/9/6/7/0/tok_db757ce5f738b09eeef5e85517d01dc9/w300_h200_x431_y253_Process_Mersmann_Bild_2-bfc143932c65fe4e.jpeg)