Clean, dry compressed air at the point of use

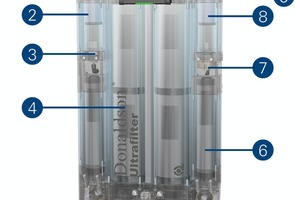

There are high demands on the processing of compressed air, which is required in large volume flows for cement production. In central compressed air stations, adsorption dryers and filters downstream of the compressors ensure that water, oil aerosols and solid particles do not get into the widely ramified compressed air network. Especially the compressed air lines, which are exposed to minus temperatures in the winter months, would freeze up if the compressed air is moist. The dryers must extract compressed air down to pressure dew points of up to – 70° C residual moisture. High-performance filters (Figure 1) for volume flows of over 1000 m³/h are installed downstream of the dryers.

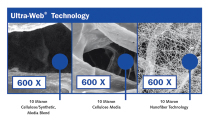

The UltraPleat™ filter technology has a high dirt-holding capacity with low flow resistance and ensures the purity of the compressed air according to ISO 8573-1, which is required for a wide variety of tasks, e.g. as conveying air or as control air for valves and cylinders and for the “shock blowers”.

However, this central compressed air supply often does not reach all compressed air consumers in the widely spread plants or the compressed air quality is not sufficient for the special requirements. In order to provide absolutely pure dry compressed air at the point of use, e.g. in the test laboratories or for the supply of sensitive control units for coal dust dosing for kilns, Donaldson developed the Ultrapac™ Smart compressed air purification system (Figures 2 and 3), in which all process steps are combined - from pre-filtration to drying to fine filtration and condensate removal. The compact stand-alone version can be used directly as a plug & work solution. The advantage: This means that the complex installation and piping of the individual components (pre and after-filters and separate adsorption dryer) and their control units is no longer necessary.

Compressed air purification with the autonomous Ultrapac Smart system is carried out in three stages:

1. the integrated pre-filter retains solid particles and suspended matter as well as liquid aerosols (oil/water)

2. the adsorption dryer stage adsorbs the moisture in the compressed air up to a pressure dew point of -70° C, at 70 % nominal load (standard -40° C)

3. in the last step, remaining solid particles up to 0.01 μm are retained in the integrated after-filter

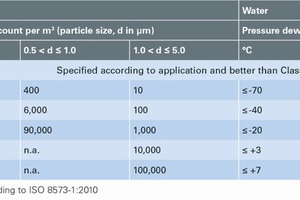

This reliably ensures a compressed air quality according to ISO 8573-1:2010, which corresponds to quality classes 1-2:1-2:1-2 and 0, specified according to the application and better than class 1.

Sustainable energy saving and quiet: pressure dew point control and low differential pressure

During the development of the system, several requirements had to be met which are essential for direct use: Controlled and consistent quality of the compressed air in accordance with the specifications for the respective application, quiet and energy-efficient operation, easy maintenance and, finally, the possibility of integrating the control system into existing production lines. The continuous recording and control of the specified pressure dew point is of particular importance. The pressure dew point is fixed at -40° C as standard. This is important as the dew point temperature changes with changing pressure. The system version with integrated dew point transmitter, which measures directly in the compressed air flow, proves to be particularly energy-saving. Switching between the two cartridges – which are filled with a highly adsorptive stable desiccant – only takes place when the desiccant is absolutely saturated. This minimizes the compressed air requirement of this heatless regenerated adsorption dryer, which, in contrast to heat regenerated dryers, does not require any heating energy for the regeneration process. The noise development during the change-over process could be reduced to the range of 60 dB(A) with a newly developed silencer. Ultrapac Smart can therefore be used directly at the workplace without sound insulation or integrated into machines without increasing their noise level.

The UltraPleat energy-saving filters used in this compressed air purification system ensure optimum filtration performance at low differential pressure. When the compressed air enters, the pre-filter effectively separates or retains liquid and solid particles before the air flows into one of the two desiccant cartridges. The post-filter, which removes solid particles up to 0.01 μm, is the effective safety element to ensure that the dry compressed air is available in accordance with the purity specifications (Table 1).

For digital applications

The greatest challenge in developing such a system was to make it compatible with existing plant technologies and processes for a wide range of applications while maintaining the same performance - whether as a stand-alone solution or modular (Figure 4). This was achieved by the flexible design and compatible sensor and control technology. A removable display allows convenient monitoring even in tight spaces. For safe operation, it is crucial that a level of digitalization is achieved with this compressed air purification system that allows continuous monitoring of the functional sequences and predictive maintenance of the easily accessible components (Figure 5).

//www.donaldson.com" target="_blank" >www.donaldson.com:www.donaldson.com