Coal combustion mechanisms and fuel NOx formation characteristics in a precalciner environment

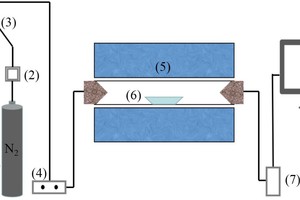

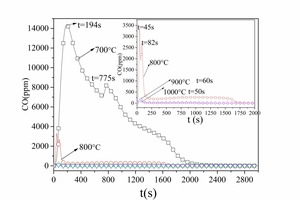

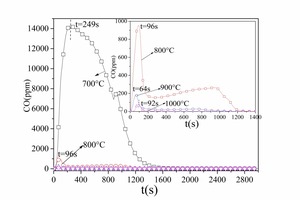

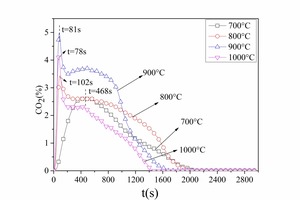

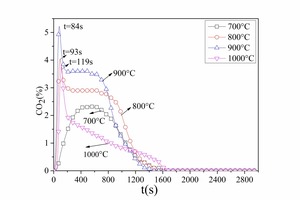

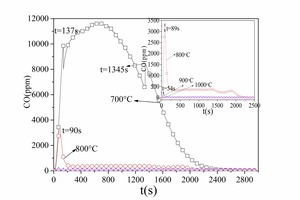

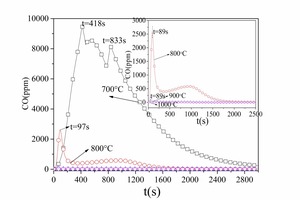

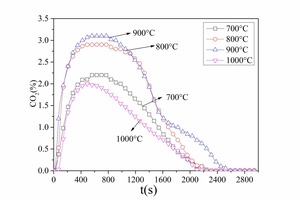

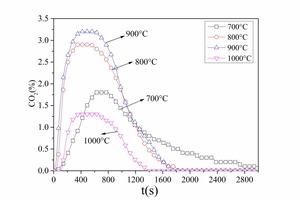

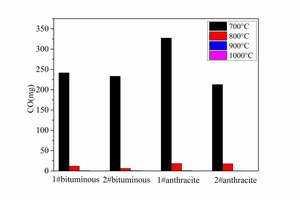

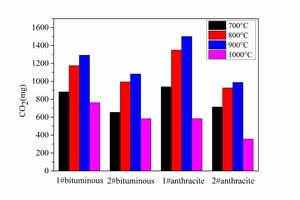

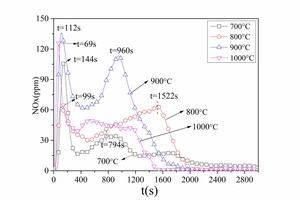

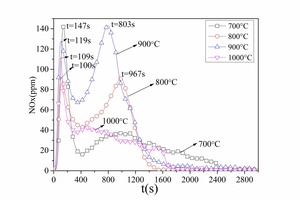

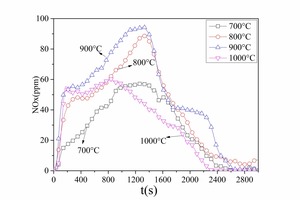

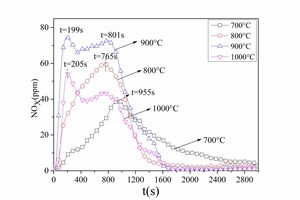

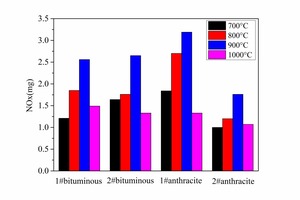

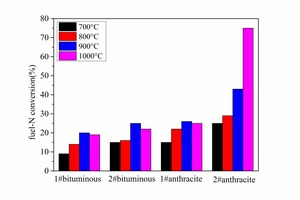

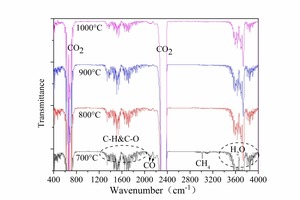

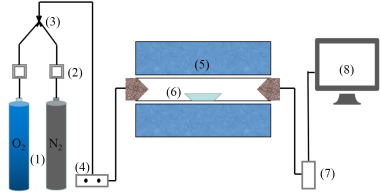

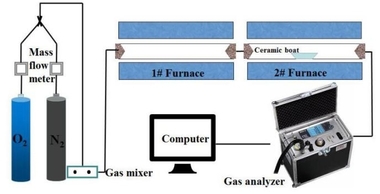

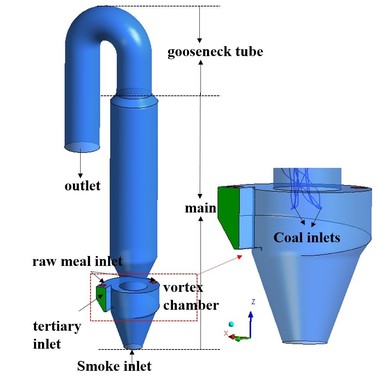

As NOx emissions become more and more severe it is important to find a method of low nitrogen combustion for coal in the precalciners in the cement industry. The operating temperature and the grade of coal have a great influence on NOx formation. The rules governing NOx formation during the combustion of two bituminous coals and two anthracite coals at 700-1000° C were therefore investigated in a double furnace reactor. The suggestions for controlling NOx emissions in a precalciner are that, to ensure efficient decomposition of the raw material, a fuel with a high volatiles content and a high fixed carbon content should be chosen and the coal should be injected into the precalciner in a zone with a temperature not exceeding 900° C.

1 Introduction

Nitrogen oxides constitute one of the main air pollutants and the NOx emission regulations for the cement industry are becoming more and more stringent. Precalciners are used in the cement industry as the main equipment for NOx reduction. In the precalciner the fuel NOx accounts for 80 % of the total NOx from coal combustion, which is the main objective in the target for NOx reduction [1-2]. Fuel NOx is formed from the oxidation of the nitrogen combined in the fuel (600-800° C) when burning nitrogenous fuel [3-6]. To develop efficient NOx reduction measures it is important to...