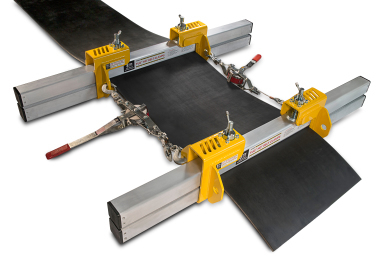

Compact precleaner with torsion spring simplifies installation in conveyor belt systems

The Flexco EZP1T is an advanced version of its proven EZP1 precleaner. The models in this series incorporate a torsion spring instead of a tension spring, which means they take up less space than the standard version. Conveyor system operators benefit from faster and easier installation. The EZP1T is available with four different polyurethane blades, depending on the application. These include a version for the extremely high temperatures encountered in mining and a version that is resistant to chemicals.

Like the standard version with a tension spring, the EZP1T is also suitable for cleaning belts with mechanical connect-ors. When a connector passes the blade, the blade quickly turns away from the belt and is immediately returned by the torsion spring to its position. There is no damage to the belt and the cleaning process is interrupted only briefly. For better cleaning of reversible belts the precleaner can be mounted at each of the two pulleys. The EZP1T is available for belt widths of 300 to 1800 mm.

Flexco offers polyurethane precleaner blades in four different versions – identified by different colors – depending on the application. All of these precleaner blades are characterized by extreme durability in their respective applications. They require less frequent replacement than compa-rable competing products – a significant advantage when it comes to downtimes and material costs.

//www.flexco.com" target="_blank" >www.flexco.com:www.flexco.com