Customer centricity is our perspective

thyssenkrupp has established itself as a full-service provider in the cement industry. We talked to Dr. Luc Rudowski, Head of Product Management, Technology, Innovation and Sustainability at the Cement Technologies business unit of thyssenkrupp Industrial Solutions, about sustainability, customer centricity, digitalization and new solutions for the cement industry.

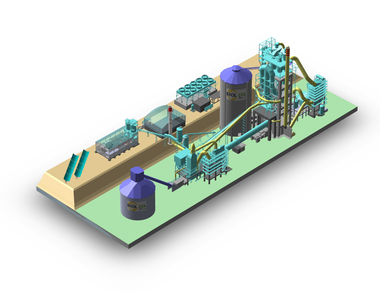

thyssenkrupp is to be separated into two companies: an industrial goods business and a materials business. The plant engineering and construction business will be one of three strong pillars of the future company thyssenkrupp Industrials, alongside the elevator and automotive supply businesses. As well as thyssenkrupp’s other capital goods businesses, the cement plant business is a truly global one and has attractive growth prospects: Worldwide, more and more people are moving to cities and need space to live and work. Urban areas will continue to grow. Cement is the most important building material for this. It must be produced in a way that is as environmentally friendly as possible. At thyssenkrupp, we build cement plants that ensure this through innovative machinery, technologies and processes. Making use of these growth opportunities takes engineering expertise, service know-how and new approaches to digitization. As a part of thyssenkrupp Industrials we will be able to fully concentrate on these success factors. This will also benefit our customers in the cement industry through enhanced product and service offers and even smarter solutions. We have established ourselves as a full-service provider to our customers in the cement industry. This means that we provide them with all products and services from a single source – from individual machines to complete EPC plants. Add this to our large portfolio of services and there are only few companies in the world that can prove a match here in terms of the quality we are offering.

I started working at thyssenkrupp, formerly Polysius, as a Sales Engineer in the 1990s. In 2004, I was appointed Head of Business Development & Sales at thyssenkrupp Industrial Solutions (France), most recently with responsibility for Business Development for all thyssenkrupp Industrial Solutions business units for the France Maghreb region. This will definitely help me in my new role as Head of Product Management, Technology, Innovation & Sustainability at the cement business unit. I am really excited to bring my customer and market focus into product development and innovation.

Customer centricity is the perspective I would like to bring to the Cement Technologies business with my new role. This is more than a mantra, this is a way to survive and grow. Listening to our customers and understanding them with all their differences in the various regions of the world, their specific needs and expectations is a must so that we can design and deliver our products, services and solutions accordingly.

Looking ahead, I think we have two priorities: de-commoditize our products and offer solutions for CO2 reduction. For both, innovation is the key. Innovation is in the DNA of our company. The challenge is to steer innovation with a customer-centric perspective in such a way that we deliver new value to our products and services faster and faster. This leads to increasing complexity in our products, which requires a change in the way we acquire the knowledge we need, and necessitates greater agility and flexibility. I also believe that innovation isn’t limited to processes and technology. If I could succeed in stimulating innovation throughout the company, across silos, across functions, across geographical areas, and perhaps across traditional company boundaries, that would be a great achievement.

There is no doubt that we are currently operating in a highly competitive space. Since Chinese competitors entered the market, even a complete cement plant built on an EPC basis has become a commodity. De-commoditization of our products is my first priority. It is an exciting challenge because we need to be innovative.

We see that as a positive challenge and we are not worried about the challenge of reducing CAPEX for our plants: We owe that to our customers. Cutting costs is part of the challenge e.g. by partnering with best-cost contractors on EPC projects or realizing worldwide sourcing and manufacturing of our products. However, the condition is to maintain the high quality standards of our products. We want to deliver high quality at better cost, not simply low cost. But this is not enough, because just relying on cost-cutting is like playing on your competitor’s field and using their strategy. We want to add value that is worth the price we offer, quality and reliability but also services and solutions throughout the product lifecycle, thanks to innovation, new business models and digitization.

Recognizing the effects of the global warming due to CO2, I personally and we as a company acknowledge there is an urgent need to make a change. In the past, the cement industry showed a lack of sustainability, making it one of the most energy intensive and environmentally harmful industries worldwide. We owe it to our customers to offer technical solutions to enable them to comply with both sustainable and economic requirements. We are ready. We can offer a comprehensive range of solutions and products to optimize the use of natural resources and energy, and lower emissions. Let me give concrete examples:

Recently, China decided to lower the NOx emission limits of cement plants to 100 mg/Nm³ in most of the provinces, with an NH3 split of less than 10 mg. Thanks to our CemCat Selective Catalytic Reduction (SCR) we can deliver a solution. We have won several orders to be delivered on a fast track basis.

Just recently, thyssenkrupp commenced production of the synthetic fuel methanol from steel mill gases in Duisburg. It is the first time anywhere in the world that gases from steel production – including the CO2 they contain – are being converted into chemicals. The start-up was part of the Carbon2Chem project that aims to use emissions from steel production as a raw material for chemicals. Surplus energy from renewable sources is used in the process to generate green hydrogen through water electrolysis for the production of methanol and other chemicals. Implemented on an industrial scale, the technology has the potential to convert around 20 million t of the annual CO2 emissions from the German steel sector. It can also be used in other CO2-intensive industries.

The use of alternative fuels in cement plants can contribute significantly to reduced primary energy consumption and nitrogen oxide emissions (NOx) and an improved carbon footprint. Our technologies permit great flexibility when it comes to the thermal use of alternative fuels. These are for example the prepol Step Combustor and our second generation polflame burner. Both technologies can be adapted to all existing cement plants, whether they were built by thyssenkrupp or other manufacturers. Both are characterized by especially low capex and opex costs.

Let me explain why: The idea of incinerating waste is not new. Waste incinerator plants have become established as a safe method of waste disposal. However, our prepol Step Combustor is an incinerator for the cement industry, but much simpler and more efficient compared to other available systems because the combustion chamber is a static system. All moving parts are located outside of it and therefore not subject to thermal stresses. The components are therefore long-lasting and easy to maintain, resulting in low operating costs and high availability. The technology can easily be integrated into existing plants and its modular structure makes it ideal for retrofitting.

With the 2nd generation of our polflame burner we offer an innovative burner for gray and white cement production. In the conventional process, the combustion of coal and heavy oil ensures the necessary flame temperatures of around 2000° C in the kiln. Instead of these fuels, the latest generation of our polflame burner is also capable of using carbon neutral refuse-derived fuels efficiently to save resources. The system is based on innovative pyroprocessing technology. It is designed for the combustion of defined single fuels as well as fuel blends. The main burner is equipped for traditional fuels such as coal, anthracite, oil, petroleum coke and natural gas as well as solid and liquid RDF such as fluff, animal meal, dried sewage sludge and wood chips. The patented burner design leads to a high and precisely adjustable supply of oxygen to the heart of the flame. This results in good ignition and burnout of the different fuels. The main burner reaches a thermal power of 10 to 300 MW.

Another important approach toward reducing CO2 emissions is the overall reduction of the clinker used by substituting it with supplementary cementitious materials. These materials include artificial pozzolans, ground blast furnace slag and fly ash. We see limited potential with slag and fly ash, for obvious reasons. Alternatively, we see strong potential with calcined clay as a cementitious material. Scientific research has evidenced the potential of calcined clay cement; the technology is available. The willingness of the cement industry to push these new cement types is necessary. We can offer technology products and a comprehensive range of services to enable our clients to take up the challenge, such as geological and mineralogical surveys, binder quality assessment, control in our lab and a lot more.

With Oxyfuel we have developed a solution for very effectively capturing virtually all CO2 emissions during cement clinker production, i.e. the CO2 evolving in particular from limestone calcination and fuel combustion. For this we use pure oxygen instead of ambient air in order to unburden the process gases from the large and useless nitrogen fraction and concentrate CO2 strongly in the exhaust gas. This gas is considerably easier to utilize than the exhaust gas from a conventional plant.

The process has been developed in a joint project with the European Cement Research Association and is planned to be demonstrated via a retrofit of two cement plants in Europe. In addition to this retrofit solution, we recently devised a solution which allows the application of the Oxyfuel technology even to new cement plants with a significant, positive effect on investment and operational costs compared with the retrofit solution. Accordingly, the cost gap between highly effective up-to-date standard cement plants and CO2 emission neutral cement plants can partly be closed.

Digitization is of course one of the driving topics of our times as it is going to transform the way we will work in the future. Cement plant operators can benefit in many ways from this development: the efficiency of the plant can be raised as well as cement quality and the overall health and safety level can be increased significantly. But of course new questions arise as well: how to integrate intelligent systems into an existing plant, how to collect the “right” data, how to train people to make the “right” decisions on the basis of the data.

As we ourselves are becoming more and more digital, we are answering those questions already and will pass this competence on to our customers. Here we are steadily combining our digital competence with our many years of engineering and process expertise. This is what we call “digitized expertise”.

For example, we are currently completely digitizing our internal project management and our construction site management. Our customers already benefit from the use of Digital Business Processes, sometimes also called BIM. BIM digitally maps a building over its entire life cycle. It brings together all building data, plans and status reports relevant to the respective project phase in an intelligent data cloud, which all project participants can access in real time. In the near future, BIM will significantly shorten construction time and accelerate commissioning – to the investor’s benefit.

Our company is playing a pioneering role in the application of Digital Business Processes in cement plant construction. We are making intensive use of it in two EPC projects for the Cruz Azul group in Mexico. The two clinker production lines have a total capacity of 12000 t of clinker per day. In the future, we will be able to digitally map the entire production process including digital control of all energy and resource flows.

Another exciting project we are currently working on is drone automation. Depending on customer requirements, drones are equipped with special sensors that automatically fly off and monitor the plant. The data obtained from these sensors then serve to avoid unwanted downtimes, record optimization potential and, above all, make our customers’ systems much safer. This clearly goes in the direction of full predictive maintenance, but especially in brownfield plants we are now offering a wide range of analytics services and products.

An integrated data system is the basis for a successful digitization. This requires close collaboration between different partners, starting with colleagues and going through to suppliers and customers. That’s what one can call a real transformation. It is crucial that the added value of digital solutions and services becomes clearly visible to our customers; for example, by providing concrete recommendations for the optimization of their plant operations. To ensure this, we combine artificial intelligence with the human intelligence of our employees.

In matters of data sovereignty and security, the aspect of trust plays a decisive role. We have been in the market for decades and maintain long-term relationships with our customers. Reliability is deeply anchored in our company’s DNA. Of course we will follow this approach of gaining reliability through partnership also when it comes to digitization and data sovereignty.

Besides that, let me make one thing clear: data sovereignty is and will always be with the customer. He decides what data he wants to share. Of course, our customers already share sensitive data with us. As a European-based company, we ensure high security standards and will continue to do so in the future. We guarantee secure data storage in our cloud and secure data exchange. Among other things, we rely on the “Industrial Data Space” (IDS), an initiative of the Fraunhofer ISST, the goal of which is to create a secure data room.

The cement industry has to keep providing low-price building materials worldwide while at the same time managing the challenges of sustainability. When it comes to reducing global CO2 emissions, it is certain that the cement industry will need to play a crucial role, for example by upgrading its technologies for carbon capture, storage and usage. We are part of this development and will partner with our customers and suppliers to create real value for the industry.