Development of composite cements characterized by low environmental footprint and appreciable performance

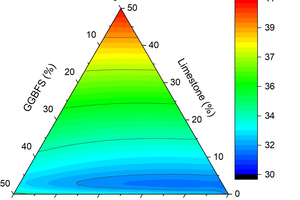

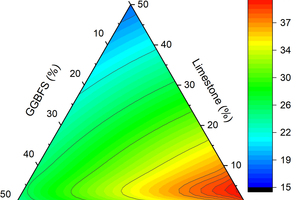

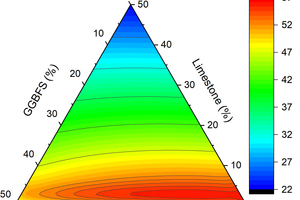

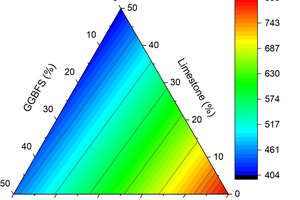

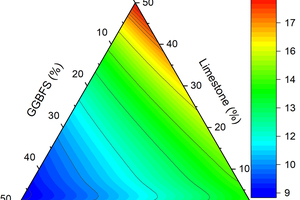

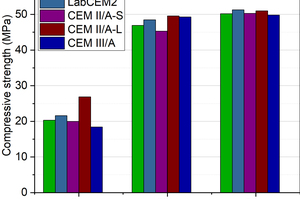

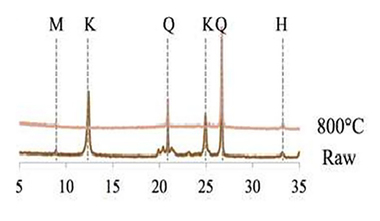

This contribution reports on the optimization of the multicomponent CEM II/C-M (S-LL) cement, a cement type which is intended to be introduced with a revised version of the EN 197-1. The replacement of Portland cement clinker has been maximized by a combination of granulated blast-furnace slag and limestone while meeting an adequate cement performance and minimizing its environmental impact.

1 Introduction

The partial replacement of Portland cement clinker by supplementary cementitious materials (SCM) is more and more in the focus of cement research. The main reason for this development is the potential to limit the CO2 emission associated with the production of Portland cement clinker [1]. The availability of highly reactive main constituents in accordance with EN 197-1, e.g. of granulated blast-furnace slag, are limited to meet the demand of only about 20 wt.-% of global cement production and are unlikely to increase [1]. The application of another well-known SCM, limestone, is...